ULTRASONIC INSPECTION OF COMPOSITES

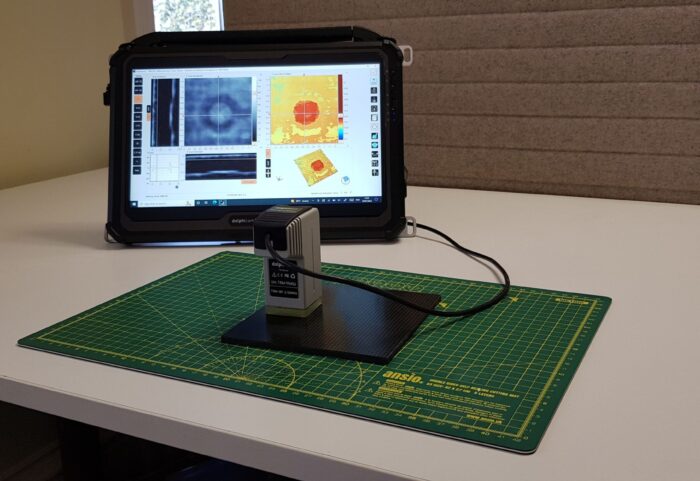

dolphicam2 is designed for the inspection a range of composite materials including, Carbon Fibre Reinforced Polymers (CFRP), Glass Fibre Reinforced Polymers (GFRP),metallics and bonded structures. What makes Dolphitech unique is our core technology, Matrix Array Ultrasonic Testing (MAUT). Matrix Array is the most powerful and data rich NDT equipment on the market. Offering the operator the unrivalled ability to view materials internal features with live C-Scans. Servicing Aerospace, Defence, Energy (wind and power generation), Space, Marine & Automotive, the Dolphicam2 is designed for composite inspection. and is unrivalled in its capabilities.

WHAT ARE COMPOSITES MATERIALS?

Composite materials are specially engineered by combining two or more distinct materials with significantly different physical or chemical properties. This combination results in a composite with unique characteristics that differ from its individual components. The most common types of composites are fibre-reinforced polymers (FRP), which include materials like carbon fibre (CFRP) and glass fibre (GFRP). Given the widespread use of composite materials, Non-Destructive Testing (NDT) has become essential for detecting flaws, assessing structural integrity, and maintaining safety standards.

Common examples of composite materials include:

- Fiberglass: Made from fine glass fibres embedded in a resin matrix, fiberglass is widely used in boat hulls, automotive bodies, wind turbine blades and sports equipment due to its lightweight and high strength.

- Carbon Fibre Composites: Known for their exceptional strength-to-weight ratio, carbon fibre composites are extensively used in aerospace, automotive, and high-performance sporting goods. For instance, the Boeing 787 Dreamliner and Airbus A350 both use carbon fibre composites for the fuselage and wings, significantly reducing weight and improving fuel efficiency.

- Kevlar: A high-strength synthetic fibre, Kevlar is used in bulletproof vests, helmets, and other protective gear. Its lightweight and high tensile strength make it ideal for personal protection and military applications.

WHERE CAN YOU USE MAUT?

Use our quick reference table below to see the typical types of features that can can be detected depending on the construction of your assets.

EXPERIENCE THE DOLPHITECH DIFFERENCE

See more with our innovative NDT technology

Send in a sample to see how dolphitech can reduce inspection lead times and enhance insights

Contact usREQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.