STUDY OVERVIEW

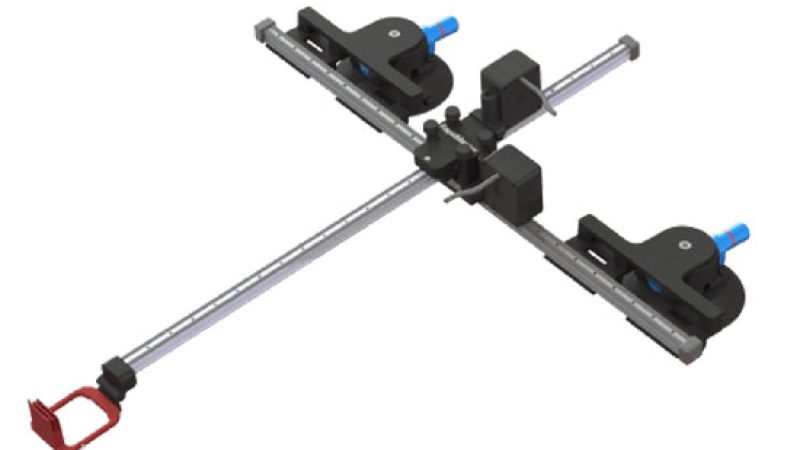

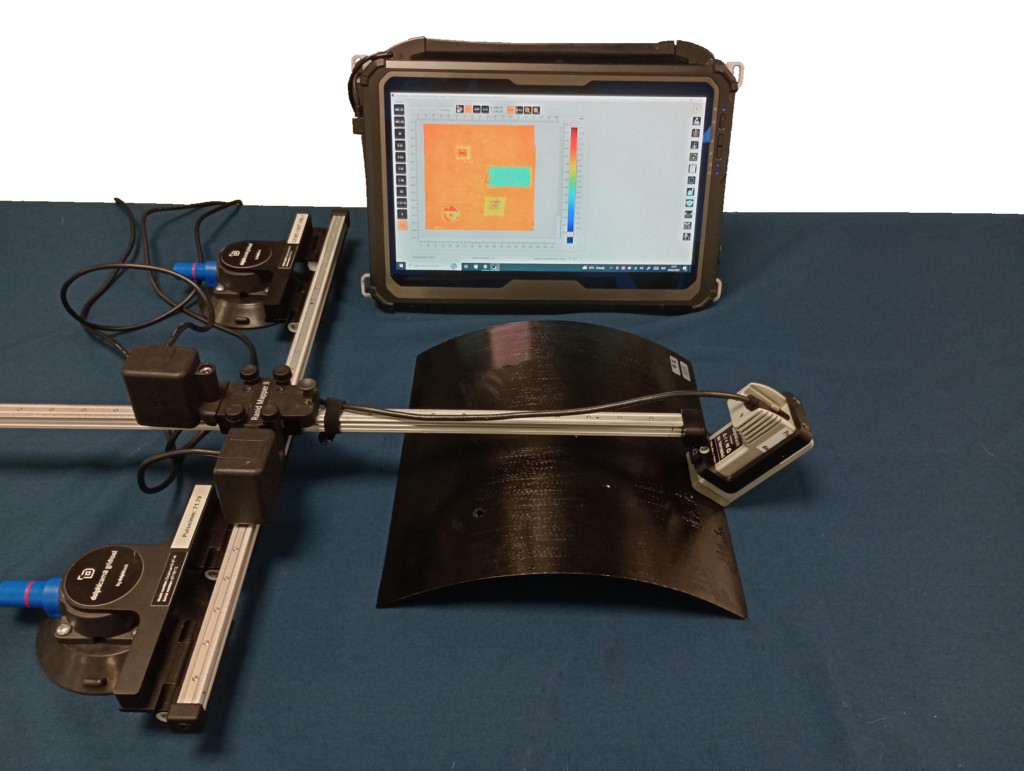

A comprehensive case study was conducted to evaluate the efficacy of using a large area mapper, specifically the Rapid Mapper MK II, for the inspection of a CFRP (Carbon Fiber Reinforced Polymer) curved surface with repair patches located on the inside of the panel. This inspection aimed to determine the tool’s capability to accurately assess the condition of the repairs and the overall integrity of the panel.

The panel in question measured 300mm by 300mm and featured four distinct repair areas. Two of these areas had additional material layered on the inside, providing a unique challenge for the inspection process. One of the repairs was circular in shape and included a hole through its center, adding another level of complexity to the task. The average thickness of the panel was approximately 2mm, and it possessed a curvature with a diameter of around 400mm.

Given the intricate nature of the panel’s design and the varied characteristics of the repair patches, the Rapid Mapper MK II was chosen for its advanced capabilities in mapping large areas with precision. The tool’s ability to encode data effectively and inspect curved geometries made it an ideal candidate for this study. Through this investigation, the goal was to validate the performance of the Rapid Mapper MK II in a practical, real-world scenario, ensuring reliable detection and assessment of repair quality.

APPLICATION OVERVIEW

The scope of the project was to thoroughly inspect the entire surface of the panel from the outer, curved side. This inspection aimed to evaluate the consolidation and bonding of the simulated repairs on the inside of the panel. This type of inspection is typically conducted as part of a repair process following damage assessment, ensuring that all repairs have been correctly executed and are holding up as expected.

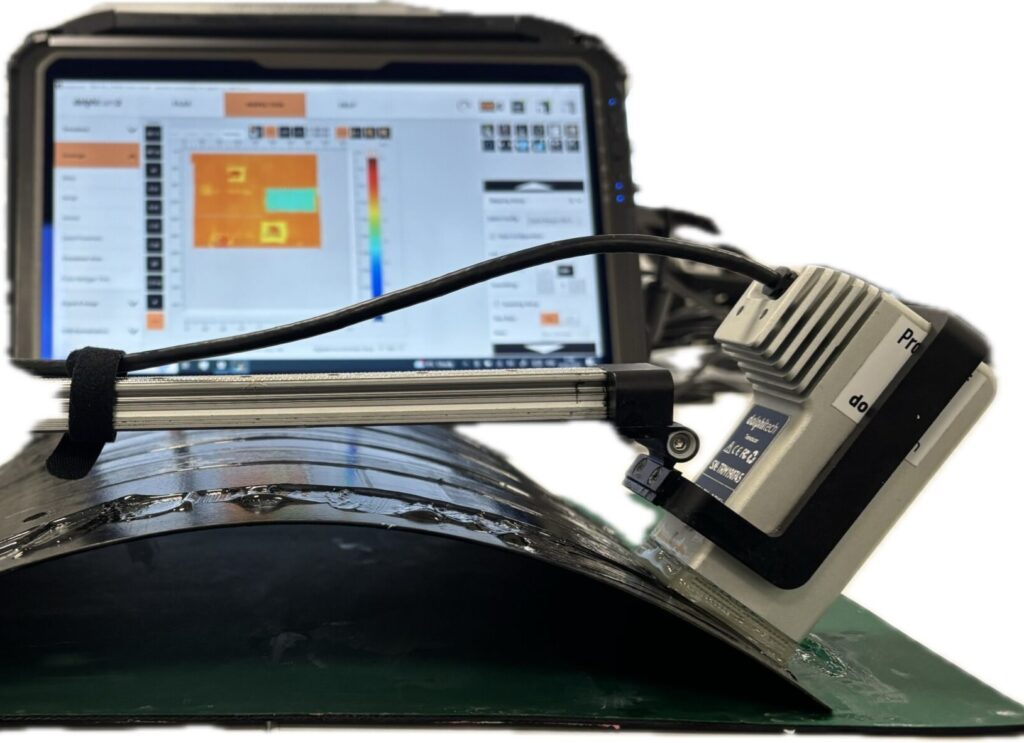

To guarantee an accurate and comprehensive mapping of the entire area in both the X and Y directions, the Rapid Mapper was selected for this task. The Rapid Mapper stands out due to its unique capabilities, which include not only encoding data in the X and Y directions but also allowing the MAUT TRM to pivot. This feature provides the system with the ability to inspect curved geometries effectively, making it particularly suitable for this application. By enabling detailed and precise mapping of the entire surface, the Rapid Mapper ensures that every aspect of the repair is thoroughly examined, contributing to the reliability and safety of the repair process.

PROCESS AND METHOD DESCRIPTION

EQUIPMENT USED

- Rapid Mapper MKII.

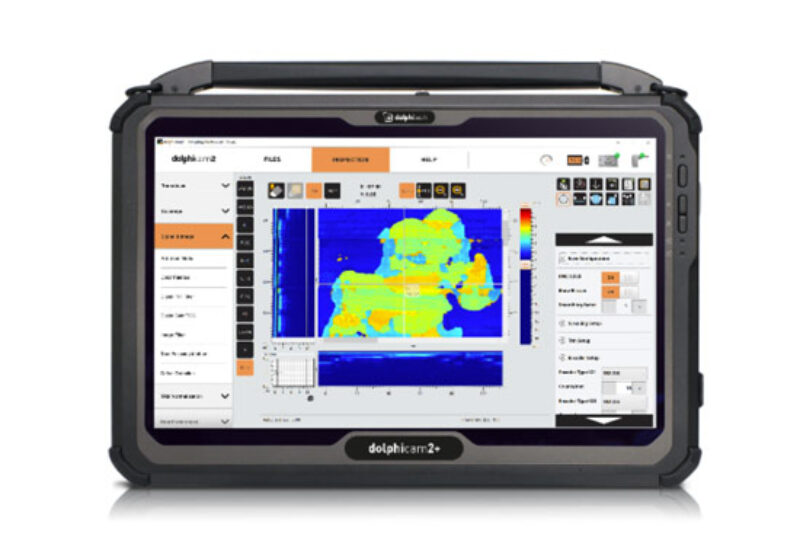

- DC2+

- TRM BFx 2.5 MHz

The standard process for setting up an ultrasonic inspection was followed before the mapping set-up was conducted. In preparation for this case study, the panel was securely clamped to the desk to ensure that the mapped data would align correctly and provide accurate results. This setup was crucial for maintaining the precision of the inspection, as any movement or misalignment could compromise the quality of the data collected.

In a real-world scenario, the mapper would typically be directly attached to the inspection surface, eliminating the need for clamping. This direct attachment allows for a more seamless and efficient inspection process, as the mapper would be firmly integrated with the surface being inspected, ensuring consistent contact and accurate data collection.

Once the full range of the mapper and the designated inspection area were properly aligned. This alignment was essential for covering the entire inspection area comprehensively and ensuring that all relevant data points were captured. By following these steps, the inspection process able to provide a thorough and accurate assessment of the panel’s condition and the effectiveness of the repairs.

FINDINGS

Utilizing the BFx 2.5 MHz TRM proved to be incredibly smooth and straightforward, largely thanks to the high resolution provided by the excellent quality of the panel material and the repairs. The process of area mapping was not only swift but also remarkably easy, attributed to the versatile design of the Rapid Mapper MK II head bracket. Its flexibility allowed for efficient and accurate mapping of the inspection area.

Although some careful probe handling was required to precisely follow the contour of the curved surface, it was still quite manageable. The entire scanning process, from start to finish, was impressively quick, taking less than 10 minutes to complete after the initial setup. This efficiency and ease of use made the BFx 2.5 MHz TRM and the Rapid Mapper MK II an ideal combination for this inspection task, ensuring high-quality results with minimal effort.

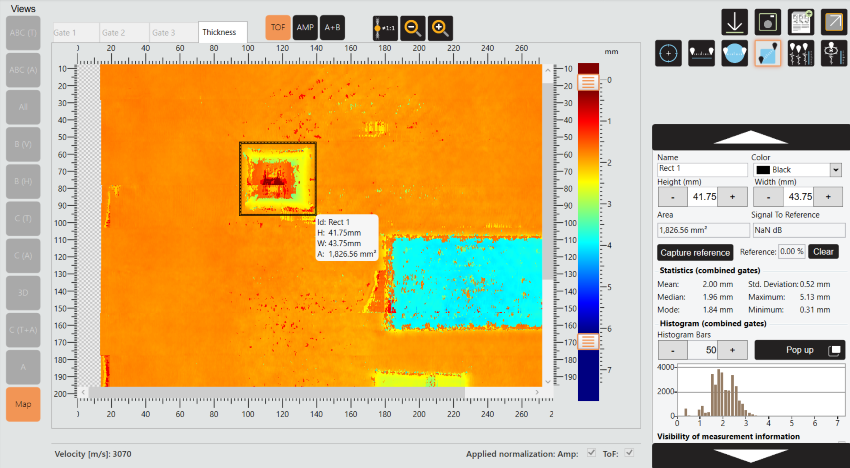

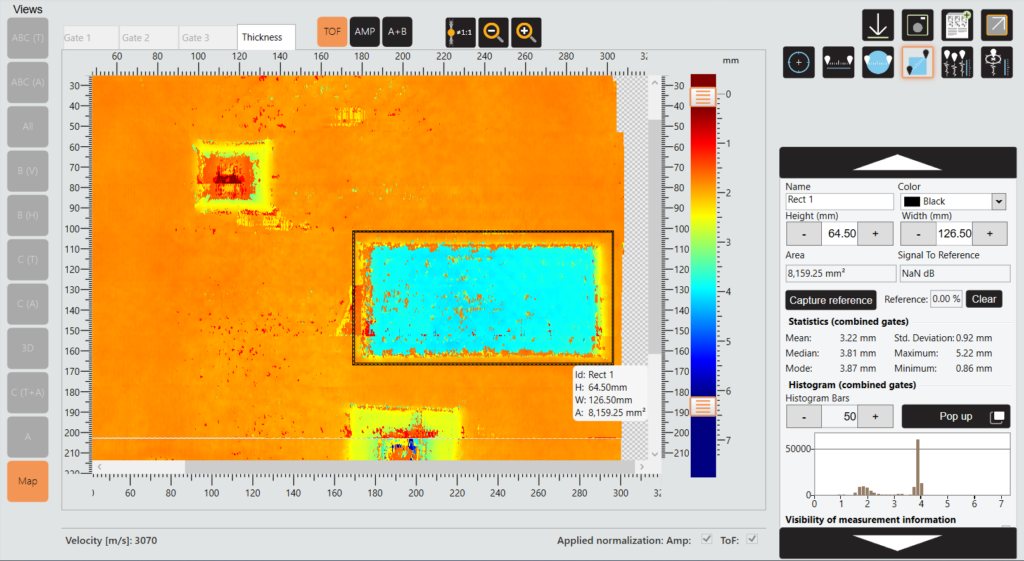

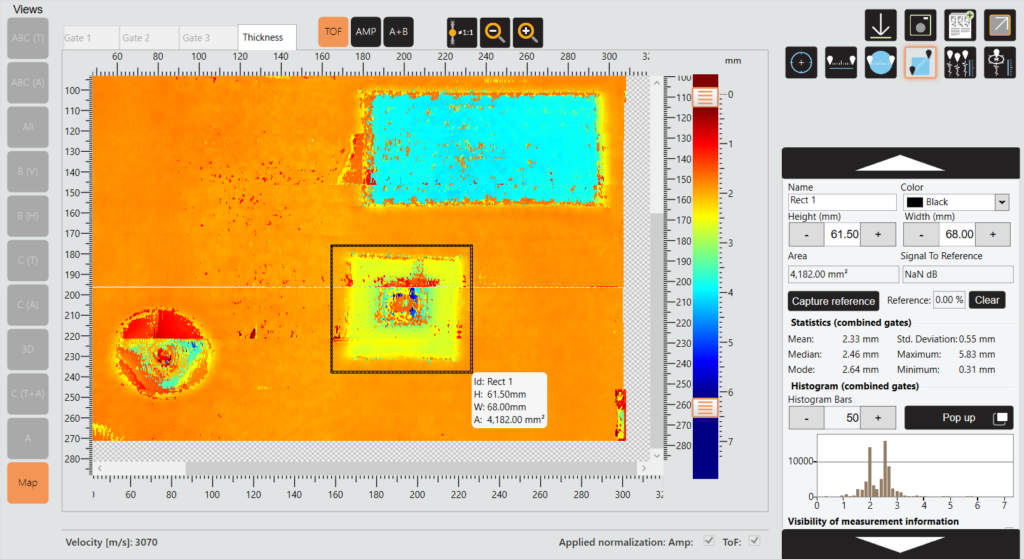

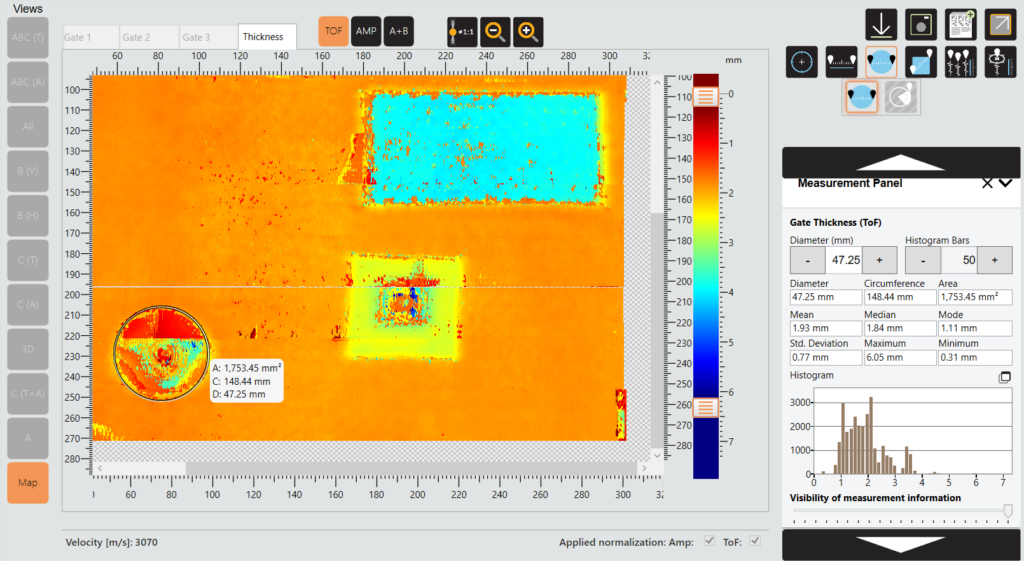

To analyse the data, the dolphicam2 analysis software was used. Eash defect area had a box placed over it and the statistical tool feature onboard was able to ascertain a number of features. Specifically, the average Amplitude, width and height and the deviation over the highlighted area.

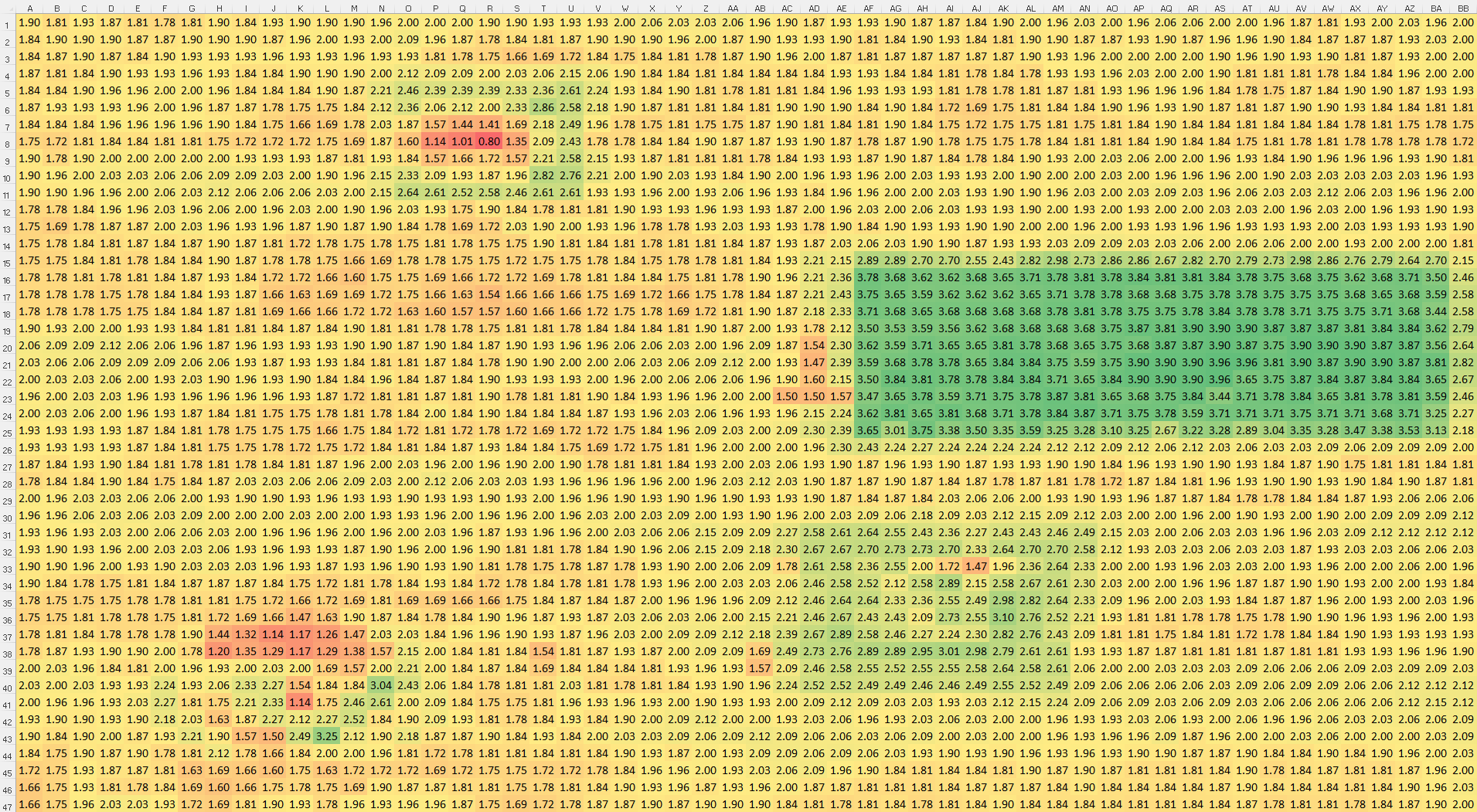

Once the data had been collected, the next step involved exporting the thickness measurements using the DolphiDepth software. This process was streamlined and efficient, thanks to the user-friendly interface and advanced capabilities of DolphiDepth. By seamlessly transferring the collected data file into the standalone DolphiDepth software, the export process was a short process.

DolphiDepth facilitates a quick and accurate export of the data, offering the flexibility to save the results in either .CSV or .XLSX formatting, depending on the user’s preference and the requirements for further analysis. The exported data was organized in a grid format, with a grid size of 5mm x 5mm, to provide a detailed and comprehensive representation of the median thickness across the inspected area.

APPLYING TO INDUSTRY

This application case study demonstrates the suitability of the inspection method for various applications involving monolithic CFRP (Carbon Fiber Reinforced Polymer) panels. Such panels are commonly found in high-performance settings, including Formula 1 (F1) cars and fast jets, where material integrity and precision are paramount.

The inspection technique is not only effective for these high-tech applications but also proves invaluable for supporting the inspection of repaired areas on CFRP panels. It enables thorough checking for bond line adhesion, ensuring that the repairs are firmly attached and integrated with the original material. Additionally, the method is adept at detecting the presence of Foreign Object Debris (FOD) within the repair, which is crucial for maintaining the overall safety and performance of the panels.

By leveraging this advanced inspection technique, engineers and technicians can ensure that both newly manufactured and repaired CFRP panels meet the stringent standards required in demanding environments. This case study highlights the versatility and efficacy of the inspection method, making it a valuable tool for a wide range of applications in the automotive and aerospace industries.

BENEFITS OF MAUT

The large TRM scan area allows for the simultaneous capture of multiple data points, significantly speeding up the scan time and reducing the overall time required for the inspector to complete the task. This efficiency is further enhanced by the ease of probe manipulation, made possible by the ergonomically designed MAUT TRM. The intuitive menu structure also contributes to a smoother operation, enabling the user to achieve the same high-quality results even when compared to the more complex setup requirements of PAUT (Phased Array Ultrasonic Testing).

Dolphitech’s software packages offer a high degree of versatility, accommodating a range of scenarios. Users have the option to complete both acquisition and analysis on the instrument itself, streamlining the process and ensuring quick results. Alternatively, the acquisition and analysis can be separated into two distinct processes, with all software capable of running independently from the equipment on a secondary PC. This feature provides an enhanced level of flexibility, allowing users to perform detailed analysis and data management with greater convenience and efficiency. By offering such adaptable solutions, Dolphitech ensures that their inspection processes can meet a wide variety of needs and applications.

CONCLUSION

For the inspection of this curved CFRP (Carbon Fiber Reinforced Polymer) panel repair, employing MAUT (Matrix Array Ultrasonic Testing) in conjunction with the large area mapper significantly enhances the efficiency of Non-Destructive Testing (NDT) evaluation. This combination enables a rapid and thorough assessment of the panel, ensuring that the quality and integrity of the repair are meticulously checked.

Moreover, this approach allows for the comprehensive data set to be stored electronically. The ability to maintain a detailed and accurate electronic record of the inspection results is invaluable. It facilitates future inspections by providing a reliable reference point, enabling easy comparison and monitoring of any changes or deterioration over time. This electronic data storage ensures that the inspection process is not only efficient but also sustainable, supporting ongoing maintenance and quality assurance efforts.

By integrating MAUT with the large area mapper, the inspection process is optimized for speed, accuracy, and long-term data management, making it an ideal solution for maintaining the high standards required in critical applications.

No block content has been added.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.