Matrix Array and Phased Array Ultrasonic Testing are two methods of Ultrasonic Technology. There are similarities, but there are also significant differences between them. Both Matrix and Phased Array Ultrasonic Testing differ from conventional ultrasound by using multiple elements to emit and receive sound waves. In contrast, a conventional Ultrasonic Technology probe uses a single crystal to generate the ultrasound, and as such, can only produce a single A-scan (line plot) at a given location.

So, what is the difference?

In the term Phased Array Ultrasonic Testing, “phased” refers to the control of the timing, and “array” refers to the multiple elements. The principle that waves interfere with each other enables phased array systems to shape the ultrasound beam. This is achieved by varying the time delay of each element’s emitted sound pulse. As such, the beam can be focused, and the beam angle can be changed electronically. Focusing improves the sensitivity at a given location, while sweeping through a range of beam angles electronically helps in situations where access to the surface is limited, or when internal features of interest do not lie parallel to the inspection surface. Phased arrays are, however, complex and require an understanding of more difficult concepts such as focal laws, which control the timing sequence of the elements’ pulsing. Also, while powerful and versatile, the set-up of a phased array inspection can be time-consuming, and interpretation of the results may be complex. Finally, as phased array probes typically only have one row of ultrasonic elements (sometimes called 1D arrays), they can only produce one through-thickness slice (termed a B-scan, D-scan or S-scan) at a given probe location. To generate a planar map of the inspection area (termed a C-scan), mechanical movement with external tooling is required, either with an encoder or a gantry assembly.

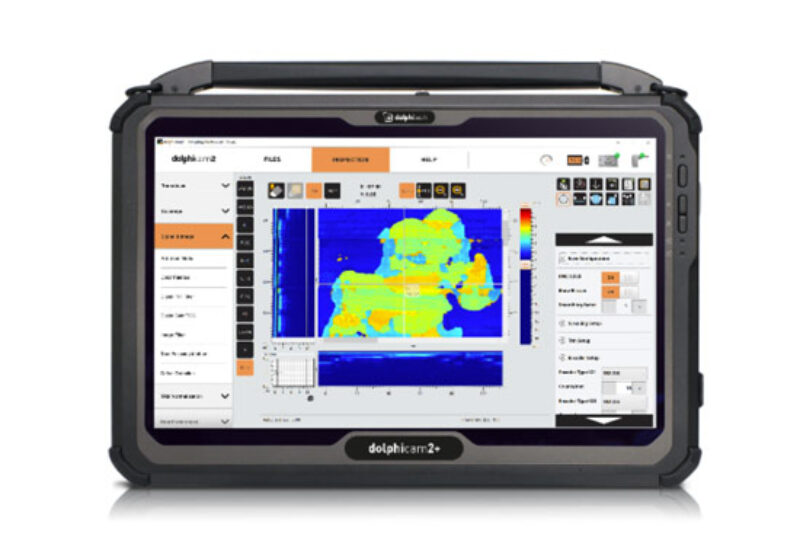

In the term Matrix Array Ultrasonic Testing, “Matrix” refers to a 2D array and in this context, a 2D array of ultrasonic elements. The dolphicam2 platform achieves this by emitting sound along electrode lines and receiving the returning signal across perpendicular electrodes. As the system uses 0-degree waves only (looking straight down into the material), it is conceptually simple to understand and produces clear data. Without the requirement to process and display phased array data, the software is tailored to show the simpler 0-degree matrix array data produced by the transducer. The matrix array means that the dolphicam2 is unique in producing live C-scans; movement of the probe is not needed. It also means that large area C-scan maps can be built up using a stitched collection of individual C-scans, without the requirement for any additional tooling. All these features combine to provide a shallow learning curve and low operator skill requirement.

To summarize, both Matrix Array and Phased Array Ultrasonic Technology are advanced non-destructive testing methods that produce imaging results, compared to the more basic line plots of conventional Ultrasonic Technology. Phased array Ultrasonic Technology can transmit sound at a range of angles and focal depths, giving it the flexibility to perform a wide variety of inspection tasks, including weld inspection. The trade-off is that phased array ultrasonics is comparatively more complex, requires more expertise, and is more expensive than Matrix Array Ultrasonic Technology. With its 0-degree ultrasound waves, Matrix Array Ultrasonic Testing with the dolphicam2 is limited to inspection tasks where features of interest lie parallel to the inspection surface, including inspection of composites, adhesive bonding, and corrosion mapping. This smaller scope means that the dolphicam2 is tailored to excel at such inspections, as well as being cheaper, easier to use, and unique in providing a live C-scan capability.