OUR ULTRASONIC TECHNOLOGY

Matrix Array Ultrasonic Testing in Aerospace

Matrix Array Ultrasonic Testing (MAUT) is more than just an innovative, user-friendly, and data-rich product suitable for all operator skill levels. At the heart of MAUT is a commitment to a safety-first mindset, which is central to everything dolphitech does.

The Role of Non-Destructive Testing in Aerospace

Non-destructive testing (NDT) is the keyholder and gatekeeper of the aerospace industry. Every day, thousands of decisions are made that ensure the safety of commercial aircraft, helicopters, and drones. These decisions are grounded in years of experience and the reliability of advanced equipment like the dolphicam2.

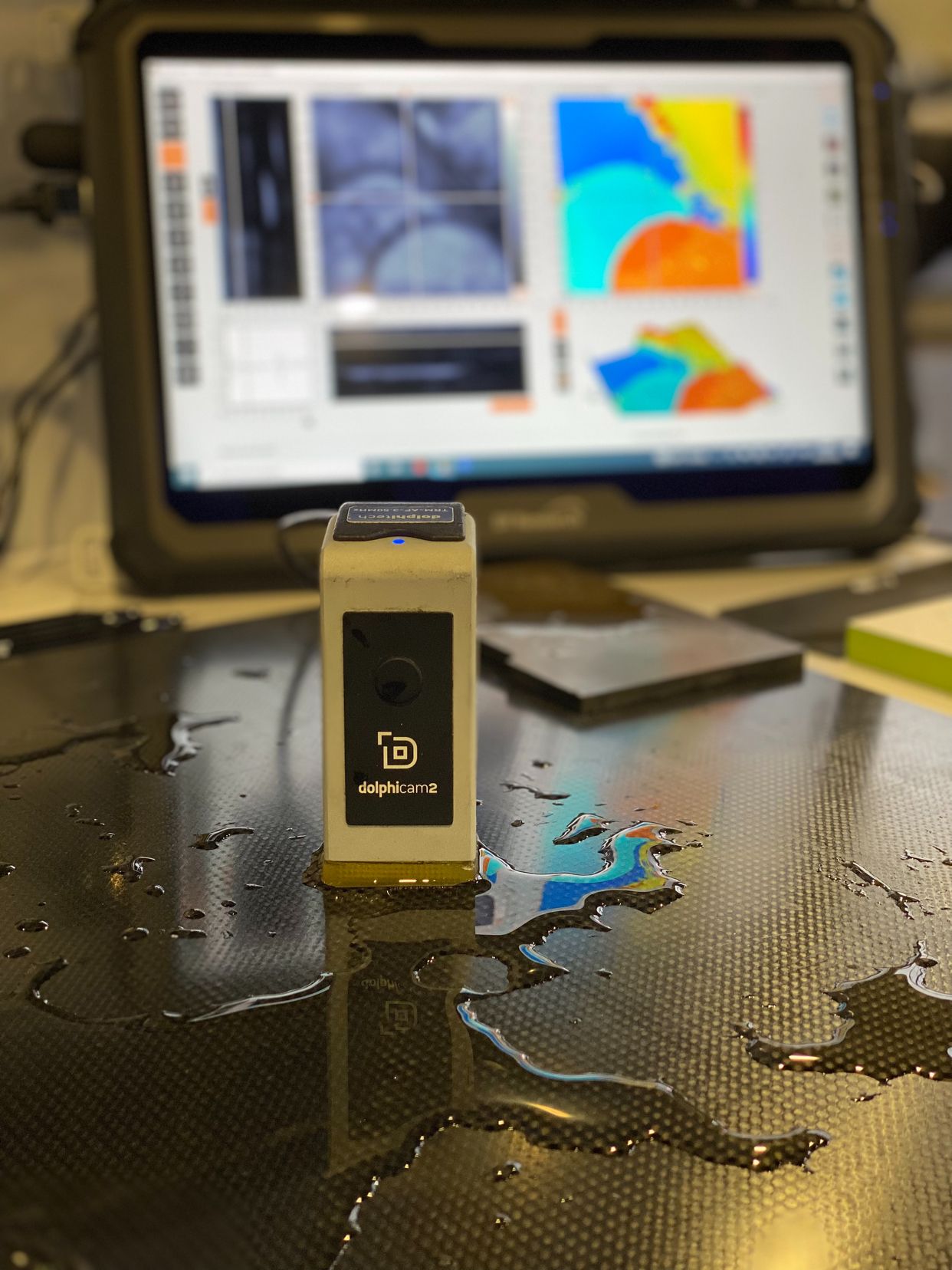

Tailored Solutions with dolphicam2

The dolphicam2’s Transducer Modules (TRMs) can be customized to suit various inspection requirements. Whether you need a fixed delay line for specific inspections or replaceable delay lines for a broader scope of work, the dolphicam2 has you covered. As a compressional UT system, it requires only a Level 2 UT NDT technician qualification, making it accessible without the extensive training needed for Phased Array Ultrasonic Testing (PAUT).

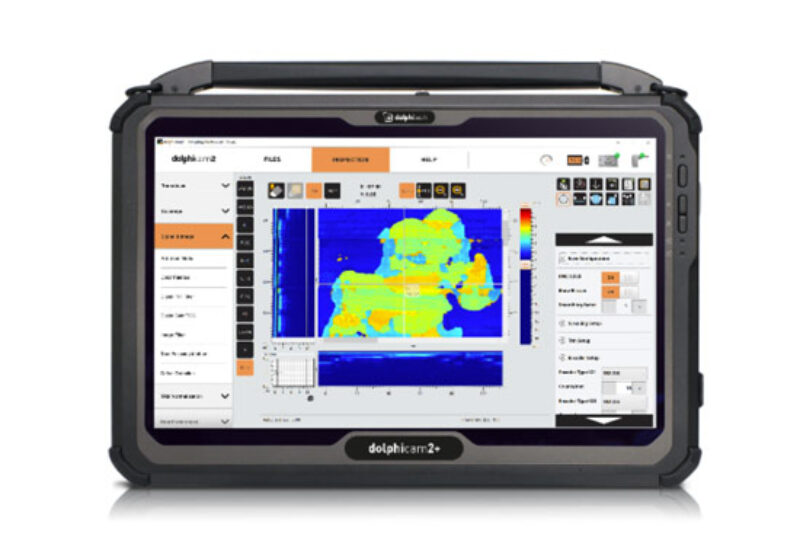

Comprehensive Data and Reporting

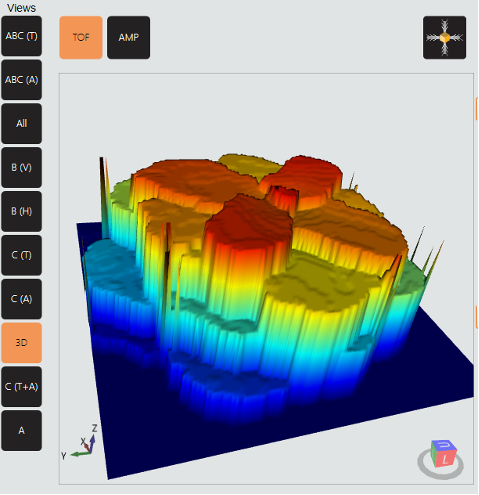

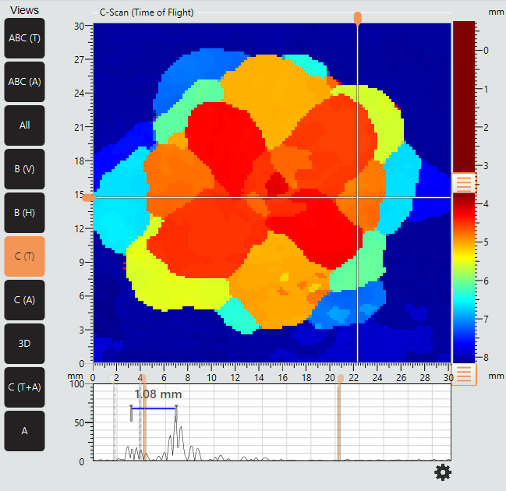

With the dolphicam2, you get all the benefits of a PAUT system, including C-Scan data (the only live C-Scan technology available), B-Scan data, A-Scan data, and unique live 3D rendering. This comprehensive data collection comes without the need for maintaining PAUT qualifications and on-job training hours. Reporting is straightforward: in just three steps, you can generate a full inspection report, which can be shared directly from the Windows-based tablet, provided you have an internet connection.

Conclusion

Matrix Array Ultrasonic Testing, exemplified by the dolphicam2, is at the forefront of ensuring safety in aerospace. By integrating advanced, user-friendly technology with a safety-first approach, dolphitech is helping to maintain the highest standards in the industry. Whether for routine inspections or addressing unexpected maintenance needs, the dolphicam2 is an essential tool for aerospace professionals.

INDUSTRY STANDARDS

Upholding Industry Standards with dolphitech’s Approvals

Industry standards are the lifeblood of the aerospace industry, ensuring compliance, safety, and conformity. At dolphitech, we are proud to hold several key approvals that underscore our commitment to these standards.

ASTM 3370-24

Our core standard is the ASTM 3370-24, “Standard Practice for Matrix Array Ultrasonic Testing of Composites, Sandwich Core Constructions, and Metals”. This standard provides operators across all industries with the confidence that the due diligence behind our technology has been thoroughly completed, and that Matrix Array Ultrasonic Testing (MAUT) exceeds all expectations.

Boeing and Airbus Approvals

In addition to ASTM 3370-24, dolphitech holds significant approvals from both Boeing and Airbus.

Airbus Commercial Aircraft: Our approval with Airbus is generic and evaluated on a case-by-case basis. If our equipment meets the defined requirements for a given procedure and can resolve the reference reflectors at the required reference level, it is permissible. The responsibility lies with the Level 3 technical inspector to select the appropriate equipment. The dolphicam2 is specified in, and was used to develop, the following procedure for the Airbus A350: Task A350-A-51-94-45-00001-35-AA-A for inspecting monolithic CFRP with thicknesses of 1-18mm.

Boeing Commercial Aircraft: Boeing has incorporated the dolphicam2 platform into their NDT manual for the Boeing 787 family (787 Non-destructive Test Manual, Part 4-51-00-22). This procedure is used for inspecting delamination’s and skin-to-stiffener disbonds in BMS 8-276 solid laminate CFRP at thicknesses up to 0.5” (12.7mm). Additionally, when a procedure does not specify a particular UT system, the dolphicam2 is permissible for use, provided it meets the necessary requirements.

Ongoing Collaboration and Future Developments

dolphitech continues to work closely with both Boeing and Airbus to expand the NDT manuals where the dolphicam2 is listed. We also have exciting developments with other aircraft OEMs in the pipeline. Stay tuned for more information in 2025.

By adhering to these rigorous standards and obtaining these critical approvals, dolphitech ensures that our technology not only meets but exceeds industry expectations, reinforcing our commitment to safety and reliability in aerospace.

AEROSPACE MANUFACTURING

Ensuring Safety in Aerospace Manufacturing with Ultrasonic Testing

In the aerospace industry, where precision and safety are paramount, the integrity of every component is critical. Ultrasonic testing (UT) has emerged as a vital non-destructive testing (NDT) method, ensuring the reliability and safety of aerostructures throughout their lifecycle.

The Role of Ultrasonic Testing in Aerospace

Ultrasonic testing uses high-frequency sound waves to detect internal flaws or characterise materials. This technique is particularly effective for inspecting composite materials, metals, and bonded structures commonly used in aerospace manufacturing. By sending sound waves into a material and analyzing the reflected signals, inspector can identify defects such as disbonds, voids, and delaminations that are not visible to the naked eye.

Safety First: Why UT is Crucial

Early Detection of Flaws: Ultrasonic testing allows for the early detection of internal defects that could compromise the structural integrity of aircraft components. Identifying these issues before they lead to failure is essential for maintaining safety standards.

Non-Destructive Testing: Unlike other testing methods that may damage the component being tested, UT preserves the material’s integrity. This is crucial in aerospace, where components are often expensive and complex to replace.

Precision and Reliability: UT provides highly accurate and reliable data, enabling manufacturers to make informed decisions about the usability of components. This precision helps in maintaining the high safety standards required in the aerospace industry.

Applications in Aerospace Manufacturing

Composite Material Inspection: Modern aircraft rely heavily on composite materials for their strength and lightweight properties. UT is indispensable for inspecting these materials, ensuring they meet stringent safety and performance criteria.

Bond Integrity Testing: In aerospace manufacturing, ensuring the integrity of bonded joints is critical. UT helps in verifying that these bonds are free from defects, which is vital for the overall safety of the aircraft.

Maintenance and Overhaul: UT is not only used during manufacturing but also plays a key role in the maintenance and overhaul of aircraft. Regular inspections using UT help in identifying wear and tear, preventing potential failures.

Conclusion

Ultrasonic testing is a cornerstone of safety in aerospace manufacturing. Its ability to detect internal flaws without damaging components ensures that every part of an aircraft meets the highest safety standards. As aerospace technology continues to advance, the role of UT in maintaining the integrity and safety of aerostructures will only become more critical.

By integrating ultrasonic testing into their quality assurance processes, aerospace manufacturers can continue to build safer, more reliable aircraft, ensuring the safety of passengers and crew alike.

MAINTENANCE, REPAIR & OVERHAUL (MRO)

The Role of dolphicam2 in MRO

The dolphicam2 is a state-of-the-art ultrasonic imaging system designed for ease of use and high-resolution imaging. It is certified by leading aircraft manufacturers like Boeing, Airbus and other aircraft manufacturers for specific NDT procedures. The system is ready to use in just 60 seconds, significantly reducing inspection times and minimizing downtime. Its real-time, analysis-ready images facilitate quick and accurate decision-making, enhancing overall safety and reliability. Enhancing Aircraft Safety with Ultrasonic Testing in Maintenance, Repair, and Overhaul (MRO)

In the aerospace industry, the maintenance, repair, and overhaul (MRO) of aircraft are critical to ensuring safety and reliability. Ultrasonic testing (UT) has become an indispensable tool in these processes, providing a non-destructive means to inspect and maintain aircraft components. One of the leading technologies in this field is the dolphicam2, a portable and user-friendly ultrasonic imaging system.

The Importance of Ultrasonic Testing in MRO

Ultrasonic testing uses high-frequency sound waves to detect internal flaws or characterise materials. This method is particularly effective for inspecting composite materials, metals, and bonded structures, which are common in aircraft. By analyzing the reflected sound waves, technicians can identify defects such as cracks, voids, and delaminations that are not visible to the naked eye.

Key Benefits of UT in MRO

Early Detection of Defects: UT allows for the early detection of internal defects that could compromise the structural integrity of aircraft components. This early detection is crucial for preventing potential failures and ensuring ongoing safety.

Non-Destructive Testing: Unlike other testing methods that may damage the component being tested, UT preserves the material’s integrity. This is essential in MRO, where components are often expensive and complex to replace.

Precision and Reliability: UT provides highly accurate and reliable data, enabling maintenance teams to make informed decisions about the usability of components. This precision helps maintain the high safety standards required in the aerospace industry.

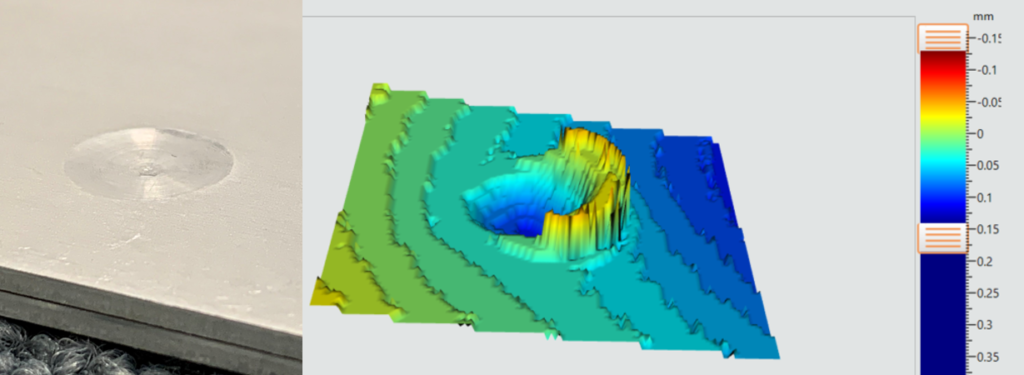

Unplanned Maintenance: Addressing BVID, Bird strikes, and Human Factors. Unplanned maintenance is a significant aspect of MRO, often triggered by unexpected events such as barely visible impact damage (BVID), bird strikes, and human errors during ground operations.

Barely Visible Impact Damage (BVID): BVID is a common issue in composite aircraft structures, caused by low-energy impacts that are not easily detectable on the surface but can lead to significant internal damage. UT, particularly with advanced systems like the dolphicam2, is crucial for identifying and assessing BVID, ensuring that any hidden damage is detected and repaired before it compromises the aircraft’s structural integrity.

Bird strikes: Bird strikes can cause severe damage to aircraft, particularly to the leading edges of wings and engines. The dolphicam2 helps in assessing the extent of damage caused by bird strikes, allowing for precise repairs and ensuring the continued safety of the aircraft.

Human Factors: Human errors, such as tool drops during maintenance, can also lead to damage in composite structures. The dolphicam2 is effective in detecting such damage, ensuring that any issues caused by human factors are promptly addressed.

Conclusion

Ultrasonic testing, with the advanced capabilities of the dolphicam2, is a cornerstone of safety in the MRO of aircraft. Its ability to detect internal flaws without damaging components ensures that every part of an aircraft meets the highest safety standards. As aerospace technology continues to advance, the role of UT in maintaining the integrity and safety of aerostructures will only become more critical.

By integrating ultrasonic testing and the dolphicam2 into their MRO processes, aerospace companies can continue to ensure the safety and reliability of their aircraft, protecting passengers and crew alike.

COMPOSITES

The Role of Composites in Aerospace

In the ever-evolving aerospace industry, the use of composite materials has become increasingly prevalent. These advanced materials are transforming the way aircraft are designed and manufactured, offering numerous benefits that enhance performance, efficiency, and safety.

What Are Composites?

Composite materials are engineered by combining two or more constituent materials with different physical or chemical properties. The result is a material that exhibits superior characteristics compared to its individual components. In aerospace, the most common composites are carbon-fiber-reinforced polymers (CFRP) and glass-fiber-reinforced polymers (GFRP), which consist of strong, stiff fibers embedded in a tough resin matrix.

Advantages of Composites in Aerospace

Lightweight: Composites are significantly lighter than traditional materials like metals. This weight reduction is crucial in aerospace engineering as it improves fuel efficiency and reduces emissions.

High Strength-to-Weight Ratio: Despite their light weight, composites offer exceptional strength and stiffness, making them ideal for critical structural components.

Corrosion Resistance: Unlike metals, composites do not corrode, which enhances the longevity and durability of aircraft components.

Design Flexibility: Composites can be molded into complex shapes, reducing the number of parts and fasteners needed. This not only simplifies assembly but also minimizes potential weak points.

Applications in Aerospace

Primary Structures: Modern aircraft, such as the Boeing 787 and Airbus A350, use composites extensively in their primary structures, including wings and fuselages. These aircraft are composed of approximately 50% composites by weight.

Secondary Structures: Composites are also used in secondary structures like control surfaces, fairings, and interior components, contributing to overall weight savings and performance improvements.

Future of Composites in Aerospace

The aerospace industry continues to innovate with composites, exploring new materials and manufacturing techniques to further enhance performance and sustainability. Research is ongoing into thermoplastic composites, which offer the potential for faster production times and easier recycling.

Conclusion

Composites are revolutionizing the aerospace industry by providing materials that are lighter, stronger, and more durable than traditional options. As technology advances, the role of composites in aerospace will only grow, driving further improvements in aircraft performance and efficiency.

SUPPORT

World-Renowned Support Service from dolphitech

At dolphitech, we pride ourselves on offering a world-renowned support service to our customers. Our technicians are strategically placed across America, Europe, and Asia to ensure we are always available to assist you. Once you become the proud owner of a dolphicam2, you gain access to several support options designed to keep your equipment running smoothly.

Online Customer Service Portal

We encourage all our customers to register their details and equipment on our online customer service portal. This portal provides direct access to raise tickets, view FAQs, and ensure your queries are directed to the right person at dolphitech.

In-Field Support

Our engineers are based in different time zones, allowing us to provide in-person assistance with minimal delay. We encourage you to get to know your regional support engineer, who can offer valuable insights and guidance on both application and equipment.

Remote Support

For immediate support needs, the dolphicam2 comes with remote access capabilities. Our engineers can remotely connect to your instrument to assist with equipment queries or application questions. This feature helps overcome language barriers and provides a firsthand experience of the live inspection.

Service Packages

dolphitech offers a range of service packages to ensure your equipment is always ready. Whether you need service, repair, or loan equipment, our packages guarantee that you will never be without your dolphicam2.

Remote Calibration

With the dolphicam2, you never have to send your equipment away for calibration. It features an easy-to-follow onboard self-calibration process. Simply raise a ticket through the customer support page, and we will guide you through the rest. Our remote calibration eliminates expensive logistics and downtime. If your dolphicam2 does need to be returned, our service packages ensure you always have access to functional equipment.

SOFTWARE

Creating a Comprehensive 360° Inspection Package with dolphicam2, dolphiDepth, and dolphiSnip

In the field of non-destructive testing (NDT), having a comprehensive and reliable inspection package is crucial for ensuring the integrity and safety of materials and structures. The combination of the dolphicam2, dolphiDepth, and dolphiSnip offers a powerful solution for achieving a full 360° inspection package.

The Power of dolphicam2

As a state-of-the-art ultrasonic test equipment, dolphicam2 is designed for ease of use and high-resolution imaging. It provides real-time, live C-Scan technology, allowing users to visualize the internal structure of components with unparalleled clarity. The system is ready to use in under 60 seconds, making it highly efficient for both quick surveys and detailed analyses.

Enhancing thickness measurements with dolphiDepth

dolphidepth is the software that complements the dolphicam2, offering robust data management and analysis capabilities. It allows users to store, retrieve, and analyze inspection data seperate from the dolphicam2. With dolphiDepth, you can generate detailed average thickness reports from all or part of your data files. Need to re-measure or go back over old data? Dolphidepth is backwards compatible to older software versions. dolphiDepth is specifically designed and has been specified by a major aircraft manufacturer. As per the requirements from industry, data is fixed in a “as-scanned” condition. Which means that once the data has been acquired, there can be no changes to gate positions or velocity etc. Meaning that the data will always be representative of the point at which it was acquired.

Precision file management with dolphiSnip

dolphisnip is the reporting tool that completes the inspection package. It enables users to manage large data files with ease, seperate from the dolphicam2. dolphiSnip allows for an area, of the operators choosing, to be extracted from the original file. Maintaning all original data and creating a seperate, more manageable file size without compromising on data quality. dolphiSnip comes with some high level analysis tools to assist the operator in zeroing in on the areas of concern and therefore only needing to manage the data of a specific key areas. This tool is essential for maintaining fast communication and documentation standards, which are critical in the aerospace industry.

The Full 360° Inspection Package

By integrating the dolphicam2 with dolphidata and dolphisnip, you create a comprehensive 360° inspection package that covers all aspects of the inspection process:

Real-Time Imaging: The dolphicam2 provides live, high-resolution images of the internal structure of materials.

Thickness Measurements: dolphiDepth ensures that all inspection data is securely maintained and extracting average thicknesses are done so easily in a readily available format.

Detailed file management: dolphisnip allows for the creation of extracted data files, this not only allows for inspection analysis to be managed quicker, but also reduced the size of data transfers.

This integrated approach ensures that inspections are thorough, data is well-managed, and reports are precise and professional. The combination of these tools enhances the overall efficiency and reliability of the inspection process, making it an invaluable asset in the aerospace industry and beyond.

INNOVATIVE NDT TO ENSURE THE INTEGRITY OF YOUR ASSETS

Inspections include multiple scenarios such as impact damage, mapping corrosion and metal fatigue in the fuselage, inspecting wings or blades for fatigue damage, disbonds and cracks detection.

CASE STUDIES

Learn how dolphitech has revolutionised the world of inspections for our customers

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.