In a recent scientific paper published by Robert Gordon University, the performance of Composite Overwrapped Pressure Vessels (COPVs) post-impact was rigorously investigated. COPVs, integral across diverse industries such as automotive, defense, aerospace, and Oil & Gas, are renowned for their strength, durability, and lightweight properties. The study delves into the durability of these vessels, emphasising their excellent impact and fatigue resistance, high corrosion resistance, and exceptional stiffness-to-weight ratio.

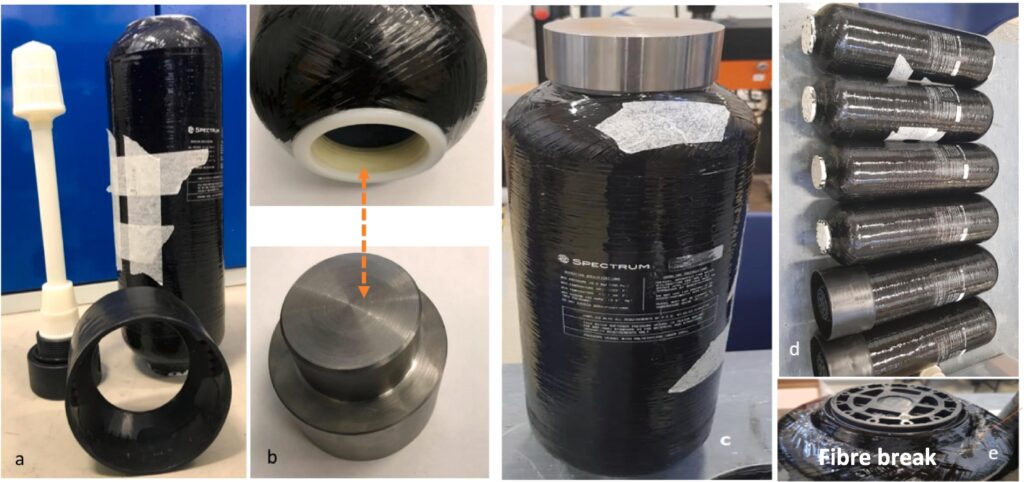

COPVs, a critical component in various industries, exhibit remarkable engineering ingenuity. Comprising a metallic or thermoplastic liner encased within a high-strength composite wrap, these vessels offer unparalleled strength while remaining lightweight and compact compared to their purely metallic counterparts. The paper further classifies four distinct types of COPVs based on their applications and performance requirements, ranging from fully metallic containers (Type I) to those with internal liners and overwrapped high-strength fibers (Types II, III, and IV) that provide reinforcement and protection.

The research involved subjecting a COPV to a battery of tests to understand its robustness. Notably, the study highlighted the challenges posed by Barely Visible Impact Damage (BVID) in composite materials, where surface damage may not accurately represent internal damage.

Enter the dolphicam2, designed by dolphitech, a critical player in this groundbreaking research. Selected for its unparalleled capability to inspect multilayer composites and dissimilar materials, the dolphicam2 proved indispensable. Its onboard analytical software delivers easily interpretable statistical data for both live imaging and post-acquisition analysis and ensures a user-friendly experience.

To assess microstructural damage, microscopy and the dolphicam2 ultrasonic non destructive testing equipment were employed.

Dolphitech’s unique 2D matrix array architecture, producing a transducer module (TRM) with 16,384 elements and an active aperture of 32 × 32 mm, offers unparalleled data capture and resolution. With a frequency range from 0.7 MHz to 10 MHz, the dolphicam2 proves its versatility, enabling the inspection of a wide range of materials.

Dolphitech takes pride in contributing to projects of this nature, demonstrating our commitment to creating efficient, data-rich, Non-Destructive Testing (NDT) equipment. Our mission remains to empower our customers, facilitating swift and reliable assessments for impactful decision-making in diverse applications.

Contact the dolphitech team to learn more about our inspection platforms.

Sources:

Industry Leader – James Njuguna FRSE