Lloyd’s Register

For over 260 year Lloyds register has been at the forefront of industry safety and compliance.

“We are a leading provider of classification and compliance services to the marine and offshore industries, helping our clients design, construct, operate, extend and decommission their assets safely and in line with environmental expectations”.

Lloyd’s Register operates in more than 70 locations, serving clients in based in 182 countries. As part of their portfolio of services offered, Lloyd’s Register validate NDT methods on behalf of industry, to ensure compliance and adherence to safety. Validating technologies like Matrix Array UT (MAUT) and certifying its capabilities gives confidence to industry, for a large range of applications.

The certification focused on ensuring that the dolphicam2 and Matrix Array Ultrasonic Testing (MAUT) technology meet industry standards and regulatory requirements for industry. Adhering to Lloyd’s Register’s stringent procedures was crucial for independent validation. This project covered the entire MAUT TRM frequency range, benchmarking against existing advanced UT methods.

Certificate Scope and Validation

Scope of Validation

This advanced ultrasonic validation aimed to ensure that the dolphicam2 and our Matrix Array Ultrasonic Testing (MAUT) technology meet industry standards, certified by a third party regulatory body. Adhering to the “Lloyd’s Register Materials and Qualification Procedure for Ships Book N, 17-3 [Validation of Advanced NDE Methods Chapter 3]” was crucial, as it provides independent validation for our customers. The project covered the dolphicam2 and the entire MAUT TRM frequency range from 0.7MHz to 10MHz in all their variants.

Peter Amin, Senior NDE Specialist, Lloyd’s Register, said: “Lloyds Register is pleased to validate dolphitech’s innovative MAUT technology, reinforcing our commitment to industry safety standards. This certification underscores our dedication to maintaining superior compliance and reliability in NDT inspection methods. Together, we are advancing technological excellence and enhancing safety across various sectors.”

To download a copy of the certificate, please follow this link to the Lloyd’s Register website.

Testing Process

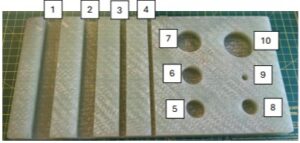

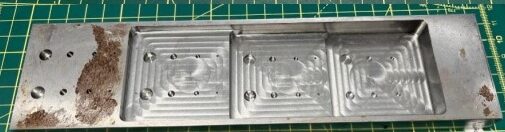

We conducted 125 tests on twelve independently verified samples to account for variations in TRM configurations. Each TRM was benchmarked against existing Phased Array Ultrasonic Testing (PAUT) technique for both metallic and non-metallic components. Before testing, all samples were verified by Lloyd’s Register to ensure they represented real-world scenarios.

Importance of Benchmarking

Benchmarking against PAUT was essential because while dolphitech’s MAUT technology offers operators a more efficient and faster inspection system, comparisons against a known technique. It was imperative to demonstrate that our technology could not only withstand industry demands but also receive the industry seal of approval from a third party industry body. Since PAUT was the only advanced UT NDE technique available, validating PAUT against our MAUT data was necessary to confirm that MAUT is not only is a faster, lighter, and easier-to-use technology, but also does not compromise on data quality.

Sample Testing

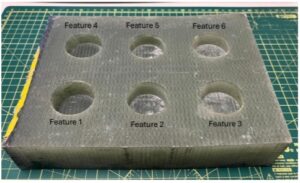

Across a range of metallic and non-metallic samples. PAUT was compared to MAUT test data. Not only did the dolphicam2 and our MAUT technology need to provide an equal level of data and accuracy as other advanced UT systems, it should also bring a new level of flexibility, speed and accuracy. For the validation, the following samples were tested:

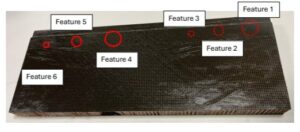

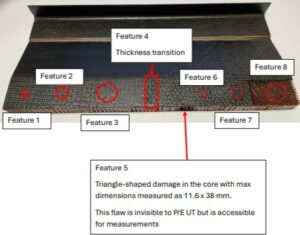

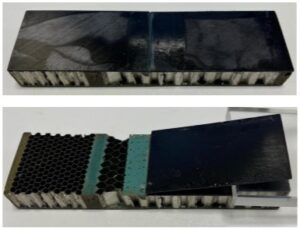

- Carbon Fibre Reinforced Polymers (CFRP)

- CFRP with porosity

- Bonded samples

- CFRP to CFRP

- CFRP to Nomex® Honeycomb

- CFRP to Aluminium Honeycomb

- CFRP to foam

- CFRP to Titanium

- CFRP to plastics

- Class Fibre Reinforced Polymer (GFRP)

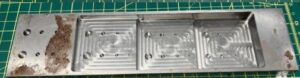

- Aluminium

- Steel

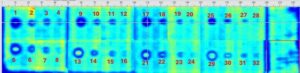

dolphicam2 MAUT Results

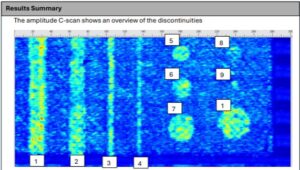

Inspection results were acquired using both single axis encoding and manual mapping method. A technique unique to dolphicam2 range, where the operator manually indexes the TRM across a 25mm grid. This allows for large areas to be mapped without the need of additional encoders to be fitted. Grid template is applied to the inspection surface using the dolphitech stitchpad, all FMC (Full Matrix Capture) data is then stitched together into a single data file.

Example test images

Advantages of using a dolphicam2

The dolphicam2+ boasts some powerful USP’s to improve and speed up inspection procedures. Features like:

- Onboard Remote Assistance

- Onboard analysis tools

- Live C-Scan imaging (for Amplitude and ToF)

- Live 3D rendering

- Up to 16,384 A-Scans across a probe footprint of 32 x 32mm

- TRM pitch of 0.25mm (for TRM frequencies 2.5MHz – 10MHz)

- Computer software – DolphiSnip and DolphiData

- Windows tablet

- Portable and Light weight

- 3kgs combined weight for dolphicam2

- 5kgs combined weight for dolphicam2+

The Application of MAUT

The validation certificate from Lloyd’s Register is a pivotal point for the application of MAUT. The validation is not only a vote of confidence in our technology, but crucially is intended to validate the use of MAUT for the inspection of materials and defects within. Structural materials common through all industries like composites (CFRP & GFRP), metallics and bonded structures are all validated via this certification. While industries can differ on their approval process, Aerospace for example, will certify a product for an NDT inspection on the component level. Where as other industries like marine or oil and gas, it is the technique that is certified.

What is MAUT validated for?

Any inspection that required the inspection of metallics, non-metallics and bonded structures. Where a longitudinal inspection (zero degree) is required to identify defects like:

- delamination

- porosity

- corrosion

- bond line inspection

- voids

- Impact damage (BVID)