About ASTM 3370-24

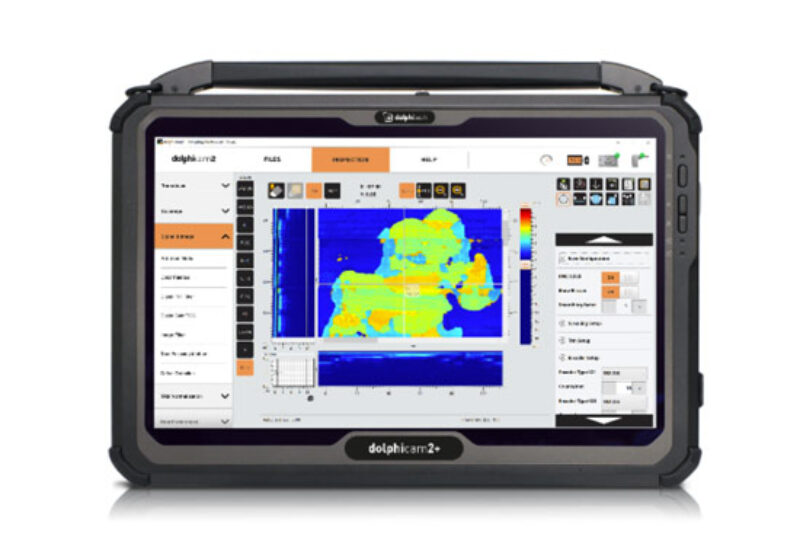

ASTM E3370-24 is now in its third iteration, representing an internationally recognized standard that dolphitech takes great pride in. This standard not only instils confidence in our customers but also underscores the global acceptance of matrix array ultrasonic testing (MAUT) as a reliable ultrasonic inspection method.

The American Society for Testing and Materials (ASTM) has introduced the ASTM E3370-24 standard, marking a revolutionary advancement in the field of ultrasonic testing. This updated standard practice provides comprehensive guidelines for the application of matrix array ultrasonic testing (MAUT) to detect and evaluate damage, discontinuities, and thickness variations in composites, sandwich core constructions, and metals. ASTM E3370-24 outlines detailed procedures for both pulse echo and through transmission techniques, making it a versatile tool for ensuring the quality and reliability of materials across various industries, including aerospace, automotive, and construction. With its enhanced capabilities and real-time data interpretation, ASTM E3370-24 sets a new benchmark for precision and efficiency in non-destructive testing.

For more details and to purchase a copy of the standard, please visit the ASTM website.

ASTM E3370-24: Overview

ASTM E3370-24, titled “Standard Practice for Matrix Array Ultrasonic Testing of Composites, Sandwich Core Constructions, and Metals,” is a significant update to the existing standards for ultrasonic testing (UT). This standard practice provides detailed guidelines for the application of matrix array ultrasonic testing (MAUT) to detect and evaluate damage, discontinuities, and thickness variations in materials.

Key Features of ASTM E3370-24

Scope and Application

– ASTM E3370-24 covers procedures for MAUT of monolithic composites, composite sandwich constructions, and metallic test articles. These procedures can be used throughout the life cycle of a part, including product and process design optimization, online process control, post-manufacturing inspection, and in-service inspection.

Techniques and Procedures

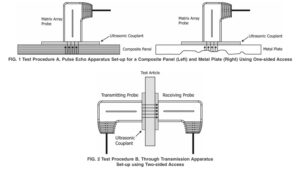

– The standard includes two main procedures: Procedure A (Pulse Echo) and Procedure B (Through Transmission).

– Procedure A (Pulse Echo) This involves a single matrix array transducer transmitting and receiving longitudinal waves. It requires access to only one side of the test article and can be conducted manually or automatically.

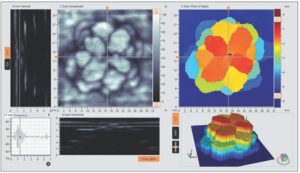

Detection of Delamination in Flat Panel Carbon-fiber Reinforced Composite Using Matrix Array Ultrasonic Testing Showing Typi

cal A-, B- and C-Scans and A Three-dimensional Rendering (Pulse-Echo Method)

– Procedure B (Through Transmission): This involves two transducers, one transmitting and the other receiving longitudinal waves. It requires access to both sides of the test article and is typically used for more comprehensive inspections.

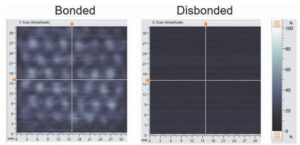

Detection of Disbond in A Sandwich Construction Consisting of A Graphite Fiber Reinforced Facesheet and An Aluminum Hon

eycomb Core Using Matrix Array Ultrasonic Testing (Through-Transmission Mode)

Capabilities and Benefits

– MAUT provides near-surface resolution and detection of small discontinuities comparable to phased array transducers. It offers real-time C-scan data, which facilitates data interpretation and shortens inspection time.

– The technique is particularly useful for inspecting multi-ply carbon-fibre reinforced laminates used in primary aircraft structures.

Types of Flaws Detected

– The standard addresses various types of flaws and discontinuities, including interply delaminations, foreign object debris (FOD), inclusions, disbond/un-bond, fibre debonding, fibre fracture, porosity, voids, impact damage, thickness variation, and corrosion.

Applications

– ASTM E3370-24 is applicable to a wide range of industries, including aerospace, automotive, and construction. It ensures that materials meet the required acceptance criteria, enhancing safety and reducing the need for rework and repairs.

Conclusion

ASTM E3370-24 represents a significant advancement in the field of ultrasonic testing, offering enhanced capabilities for detecting and evaluating damage in composites, sandwich core constructions, and metals. Its comprehensive guidelines and versatile procedures make it an invaluable tool for ensuring the quality and reliability of materials across various industries.

If you woul dlikwe to learn more about this standard or any of our products and how they are suitable for your application then please click the button to contact us

Contact us