STUDY OVERVIEW

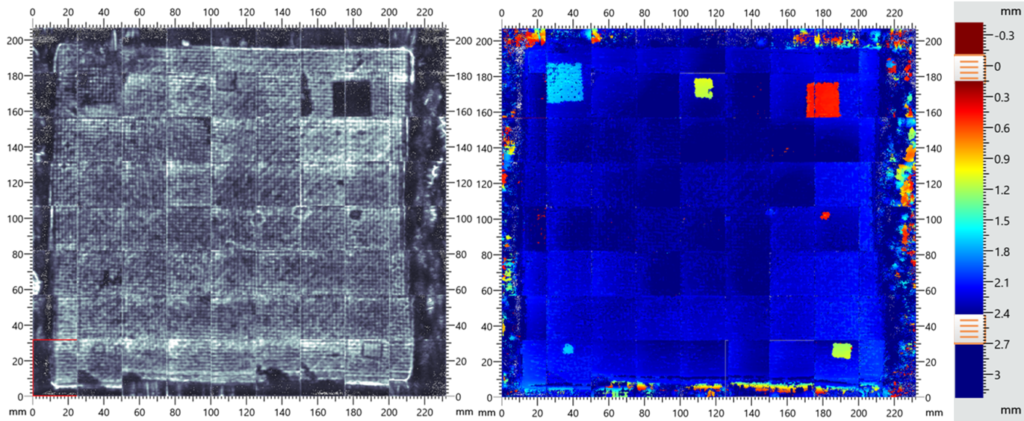

The Chester Smart Composite Group at the University of Chester provided dolphitech with a Carbon Fibre Reinforced Polymer (CFRP) panel containing a range of embedded inserts for benchmark testing. The CFRP panel was a twill weave epoxy prepreg laminate measuring 200 x 200 x 2mm. The inserts were representative of internal, inter-ply delaminations within the laminate.

SOLUTION

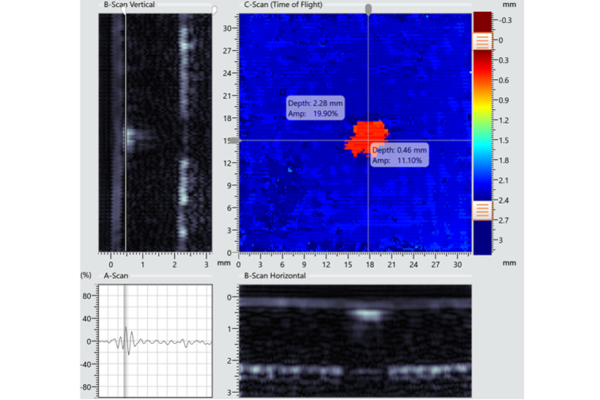

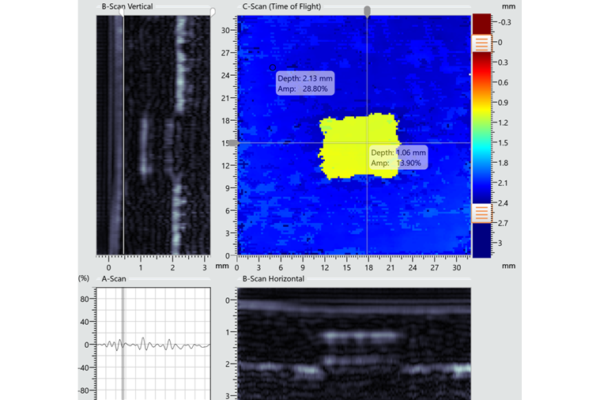

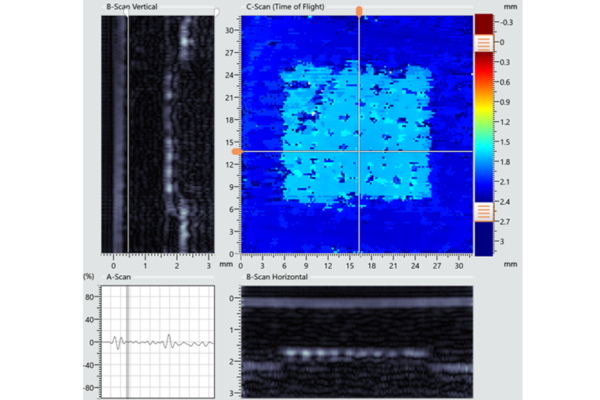

A TRM-DB-8MHz was used for this inspection, since the thin panel could be penetrated using this higher frequency. The short ultrasound wavelength of this probe enables superior resolution to be achieved both in-plane and in the through- thickness dimension. This is useful for near surface detectability, where sufficient separation of the surface echo from the indication echo is required.

FINDINGS

All six embedded inserts were successfully detected. The inserts varied both in size and in through-thickness locations. The defects near the inspection surface and the opposite backwall surface were still successfully resolved due to the 8MHz frequency used. These were within 0.5mm of each surface. The relative through-thickness locations of the defects were automatically colour-coded for easy interpretation via the Time of Flight C-scan image.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.