News

How Dolphitech are Leading the Way in Non Destructive Inspection for Aircraft Composites

Non-destructive inspection is pivotal in quality control and maintenance operations across diverse industries. Our expertise at dolphitech lies in harnessing advanced ultrasound technology to conduct thorough inspections without compromising the integrity of the inspected materials.

ViewA Comprehensive Guide to Non-Destructive Testing (NDT)

Across various industrial, automotive and aerospace industries, Non Destructive Testing (NDT) is used as a critical quality assurance tool.

ViewEnhancing The Compact Power of the “Dolphicam-In-A-Box” For Non Destructive Evaluation

DIAB revolutionises the concept of portability in non-destructive evaluation tools.

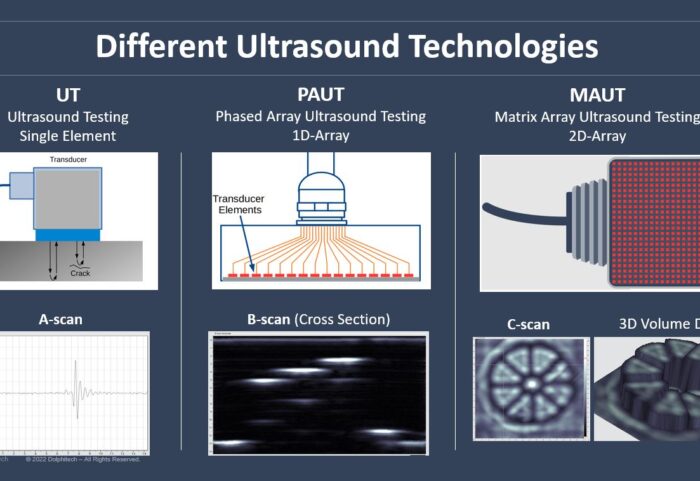

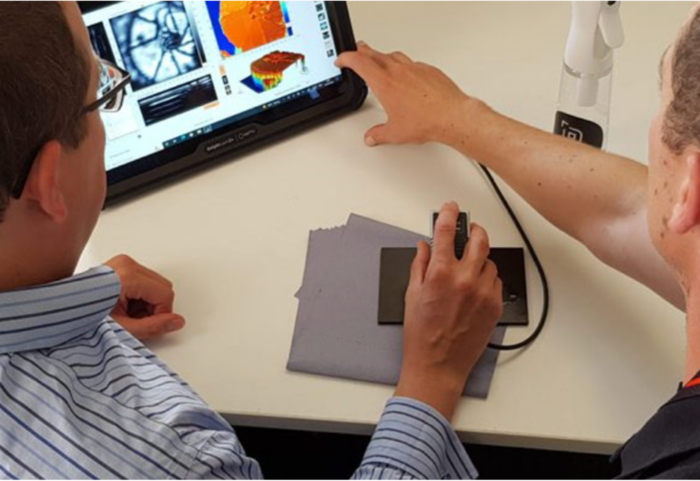

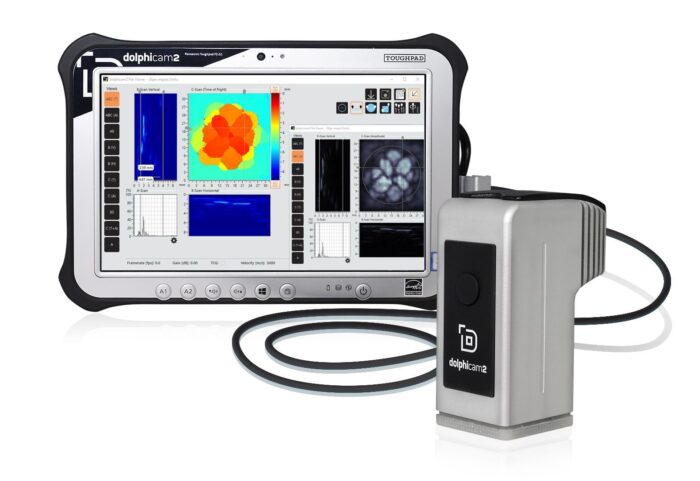

ViewExploring the Advantages of Matrix Array Ultrasonic Testing with Dolphicam2

Matrix Array Ultrasonic Testing (UT) is an innovative technology offering distinct benefits over its counterpart, Phased Array Ultrasonic Testing.

ViewDolphitech’s Comprehensive Service and Support Solutions

Dolphitech understands the critical role of non-destructive testing (NDT) equipment in various industries, ensuring the integrity of materials and components.

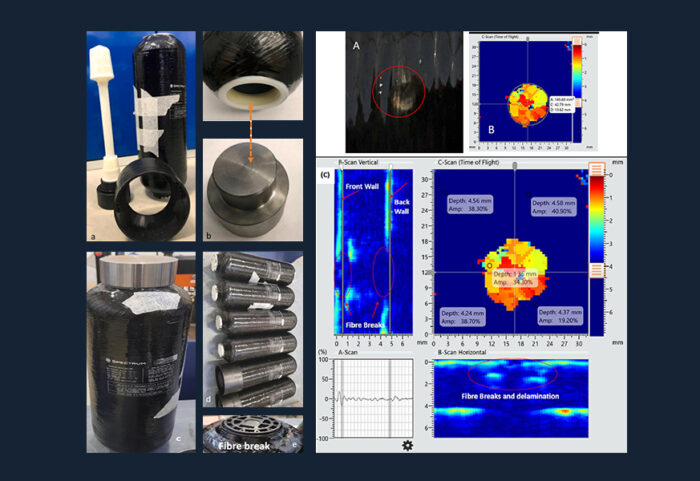

ViewDolphitech’s dolphicam2 proves instrumental in groundbreaking COPV impact durability study

In a recent scientific paper published by Robert Gordon University, the performance of Composite Overwrapped Pressure Vessels (COPVs) post-impact was rigorously investigated.

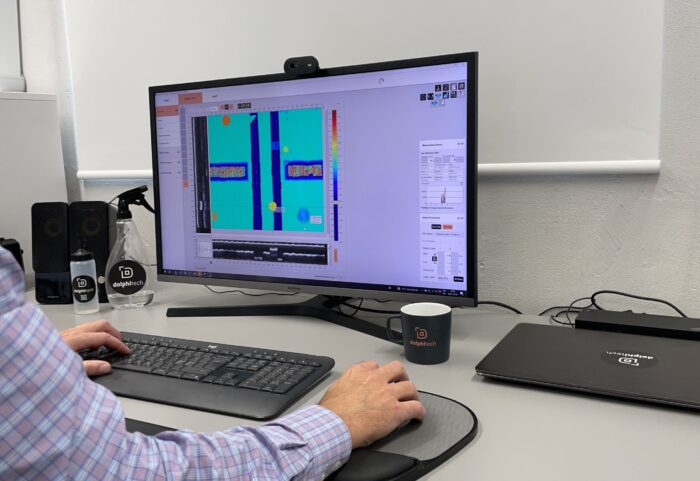

ViewEnhancing ultrasonic inspections with dolphitech’s software suite

Dolphitech provides an advanced software suite that complements the dolphicam2, enhancing the precision and efficiency of ultrasonic inspections.

ViewIntroducing dolphitech’s calibration and health check services

Dolphitech provides a comprehensive range of service solutions, including technical support, spare parts, calibrations, product updates, and repairs, to support our products.

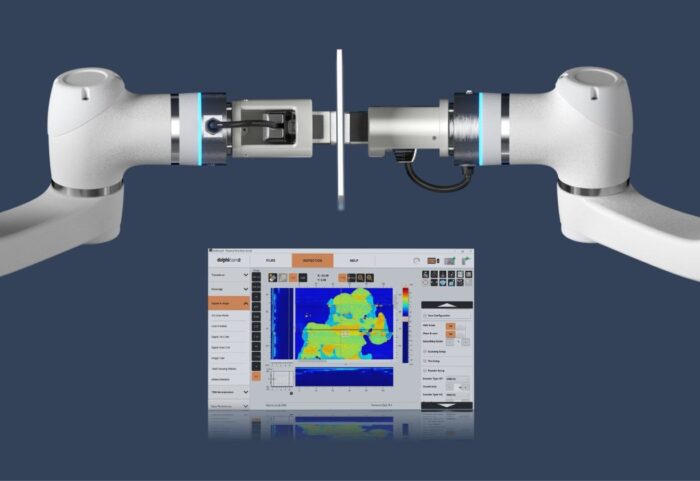

ViewAutomating your inspections

Bring reliability and consistency to manufacturing processes and seamlessly integrate into your production lines.

ViewAircraft composites & enhanced inspections

Aircraft design continues to move toward composites, meaning improved performance for operators but new challenges for maintenance technicians.

ViewThor software update

We are pleased to announce the launch of our new software update Thor bringing you even more power to your non-destructive testing with the dolphicam2.

ViewMatrix vs phased array ultrasonic testing

Matrix and Phased Array are two methods of Ultrasonic Testing (UT). There are similarities, but there are also significant differences between them.

ViewCarbon fibre in aerospace

To ensure correct processes and continued, safe performance of carbon fibre aircraft, Non-Destructive Testing (NDT) is used throughout a product’s lifecycle.

ViewGo deeper with your NDT inspections

The new 0.7 MHz transducer module (TRM) is the first in our X-Series to launch. It is well-suited for the inspection of very thick GFRP sections and low-grade GRP materials.

ViewUltra versatile for military forces

The dolphicam2 provides reliable testing of military assets to keep military forces safe and able to perform.

View