MAXIMISE WIND TURBINE UPTIME WITH FAST, ACCURATE

INSPECTIONS OF BLADES AND COMPONENTS

As the energy transition gains momentum, the ways that companies are meeting their customers’ power needs have grown to encompass a diverse energy portfolio. Conventional and renewable energy sources are changing, with wind, nuclear, geothermal, oil and gas, all bringing their own challenges. With downtime commanding a premium, ensuring the integrity of equipment, materials and components lie at the heart of energy generation success.

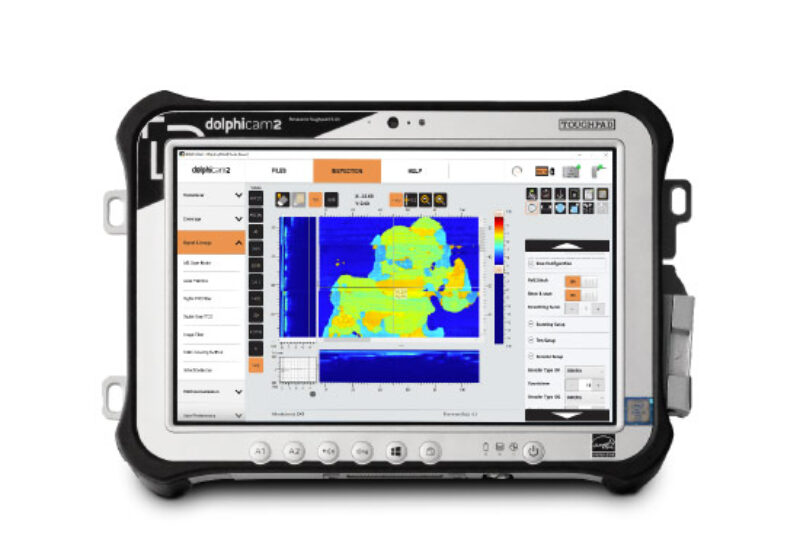

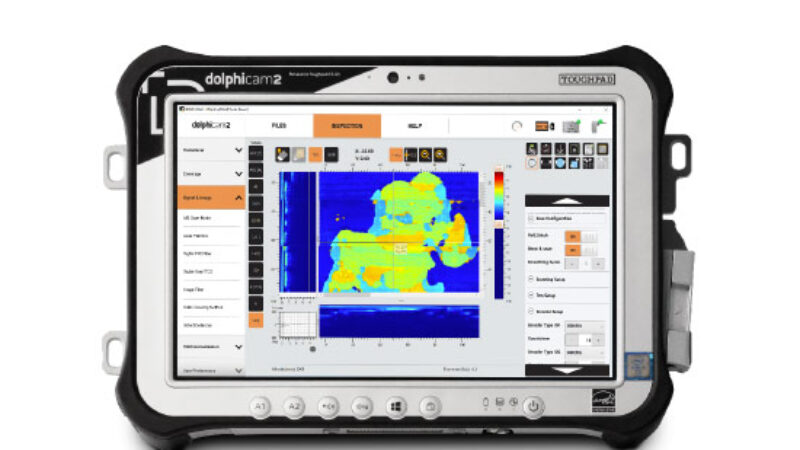

Our cutting-edge Ultrasonic Testing (UT) inspection technology can confirm sizing for defects, damage, and degradation early, before your issues lead to discontinued operations and major shutdowns. The dolphicam2 is ideal for detecting and characterising flaws in wind energy assets, including lightning damage delamination, heat damage, impact damage, disbonds, corrosion, cracking and more.

UNRIVALLED, PATENTED ULTRASONIC IMAGING WITH REAL-TIME RESULTS

Dolphitech’s intelligent approach to problem-solving has delivered cutting-edge Ultrasonic Technology (UT) equipment to the market, providing powerful visualizations of your inspection data instantly. The knowledge you will gain using our dolphicam2 enables improved safety and assurances and as a result, better decision making. From wind blades to pressure vessels, onshore and offshore, the condition of your assets is visible with dolphicam2.

INNOVATIVE NDT TO ENSURE THE INTEGRITY OF YOUR ASSETS

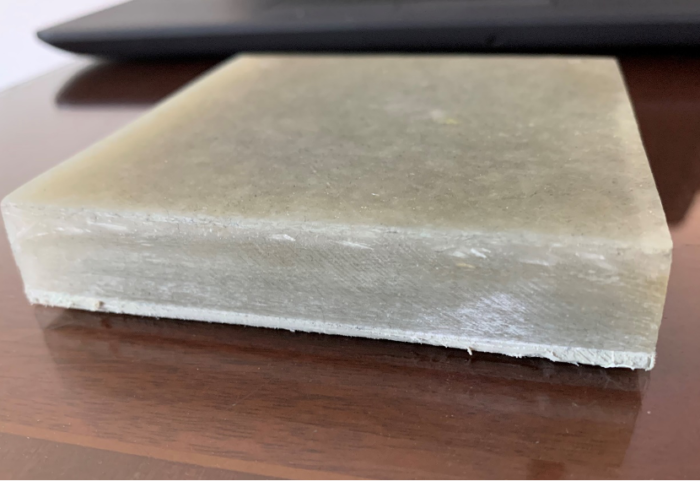

Dolphicam2 is exceptionally good at enabling quick and accurate inspection of materials common to the Wind industry such as: metals, carbon fibre reinforced polymer (CFRP), glass fibre reinforced plastic (GFRP), glass-reinforced aluminium laminate (GLARE), multi-materials and composites.

- Manufacture, fabrication, site and in-field testing

- Advanced and reliable NDT for materials, metals and composites

- Quick and easy to use and deploy

A PORTABLE, VERSATILE AND SECURE TECHNOLOGY PLATFORM

Dolphitech’s flagship UT, dolphicam2 is an ideal platform to detect and inspect damages, defects and degradations. The compact, portable, precise system is ideal for manned and robotic inspections of the materials that make up wind turbine blades.

CASE STUDIES

Learn how dolphitech has revolutionised the world of inspections for our customers

COMPREHENSIVE TRAINING AND SUPPORT

The Dolphicam2 platform requires minimum training to operate. We offer training and support so you can inspect and gather high accuracy and visualised data wherever and wherever it is required. The platform will be ready to use in 60 seconds, increasing efficiency and saving you valuable time between site visits. No more downtime while calibrating your hardware either.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.