STUDY OVERVIEW

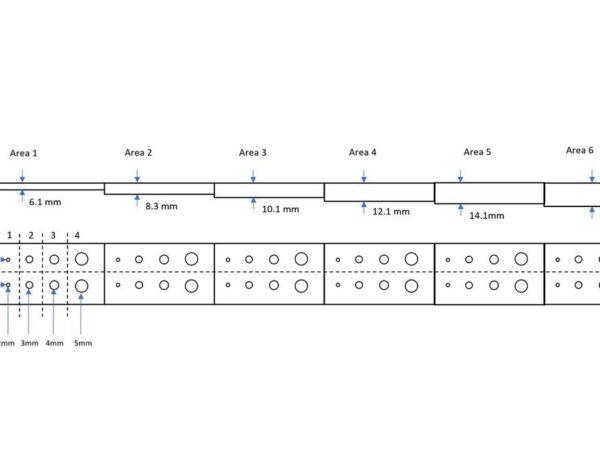

High quality composites are increasingly common in the aerospace industry due to their superior specific strength compared to metals. As such, Carbon Fiber Reinforced Polymer (CFRP) is the predominant material in the latest generation of both Airbus and Boeing airliners. Non-Destructive Testing (NDT) of CFRP is therefore critical to ensure both manufacturing quality and continued airworthiness of these aircraft. In order to assess NDT performance, reference blocks containing different features and geometry are commonly used, allowing detectability of different techniques to be compared. One such CFRP block was kindly provided to us by Airbus to benchmark the performance of the dolphicam2. It contains back surface steps of different heights, as well as flat bottomed holes of different heights and diameters. It can therefore be used to assess both the penetration and resolution capabilities of the dolphicam2.

THE SOLUTION

The 3.5MHz TRM was selected as it is an excellent choice for CFRP applications. The frequency is low enough to travel through CFRP but still high enough to get a great resolution for many inspections. This transducer is approved and recommended for use within both the aerospace and automotive industry for CFRP inspection.

CHALLENGES

CFRP, as a composite composed of different constituent materials, is inherently challenging for ultrasonic testing. This is because the different material phases absorb, scatter and deviate the sound beams. Resolution of small features that are deep in the material will be especially difficult to detect, as the sound has already been mostly dissipated and distorted by the time it reaches them.

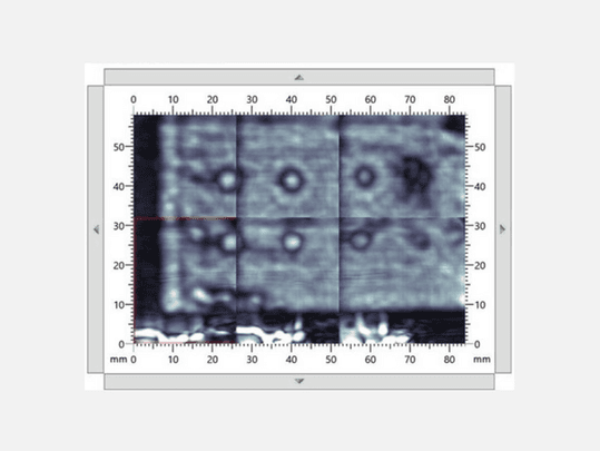

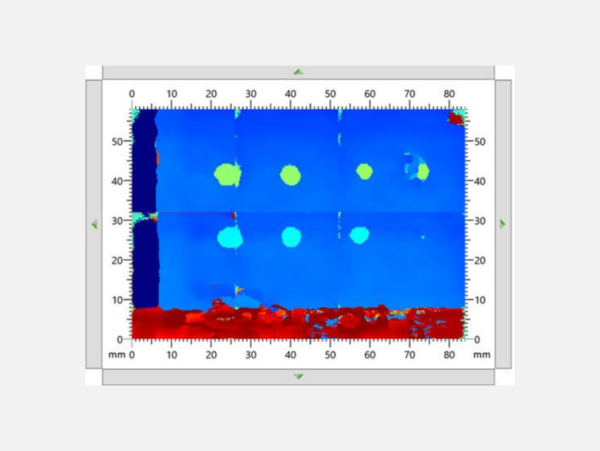

FINDINGS

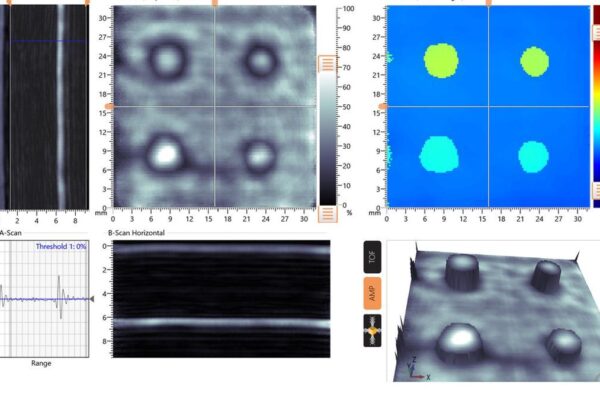

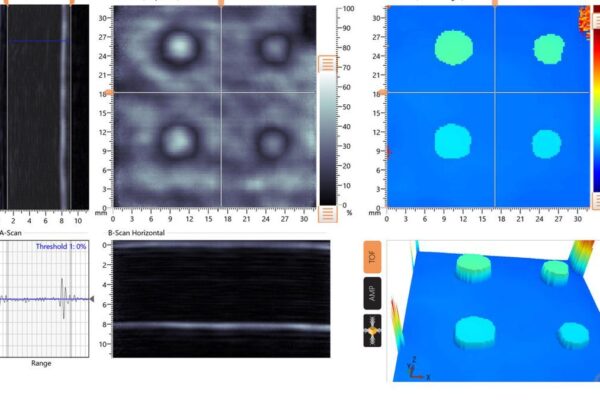

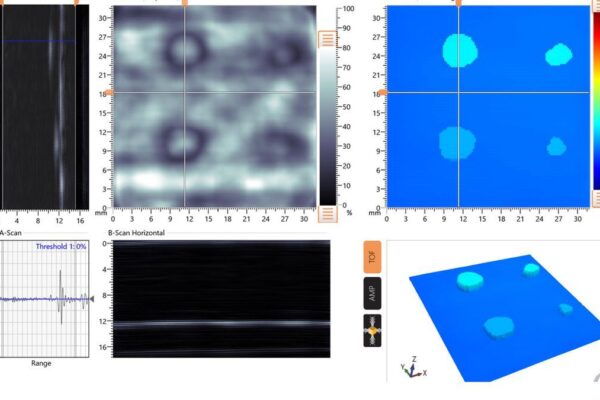

The dolphicam2 was able to resolve the back wall echo of the step block at all depths, showing successful penetration of the material. The majority of the flat bottomed holes machined into this surface were also resolved. The larger holes (4-5mm) were visible in the time-of-flight C-scan images (depicted in color), enabling easy interpretation of both their location and depth. Smaller holes (2-3mm) were not always resolved on the time-of-flight images. This is because they don’t present a large enough flat surface to reflect the ultrasound. In these instances, the amplitude C-scans (depicted in grayscale) are often still able to resolve them, as they represent a variation in the amount of sound energy reflected. As both types of C-scan image are available in real time, the user can use both to enhance detectability.

CONCLUSION

The dolphicam2 with the 3.5MHz TRM was able to penetrate the full 16mm thickness of the CFRP step block, and resolve most of the flat bottomed holes, with real-time, color-coded interpretation of their depth.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.