Our technical architects in Norway have been working behind the scenes on an exciting new product launch and finally, it’s here! We’re excited to present the next-generation digital inspection product MxTTU™ at this year’s ASNT 2021 Annual Conference in Phoenix on November 15th, 2021.

Taking to market our latest innovation, and working with end clients during development to ensure it’s a great fit for the industrial users, has been a significant change to how we work at dolphitech, and this is now reflected in how user-friendly, robust and flexible MxTTU™ to our end clients.

Jason Smith – Chief Commercial Officer

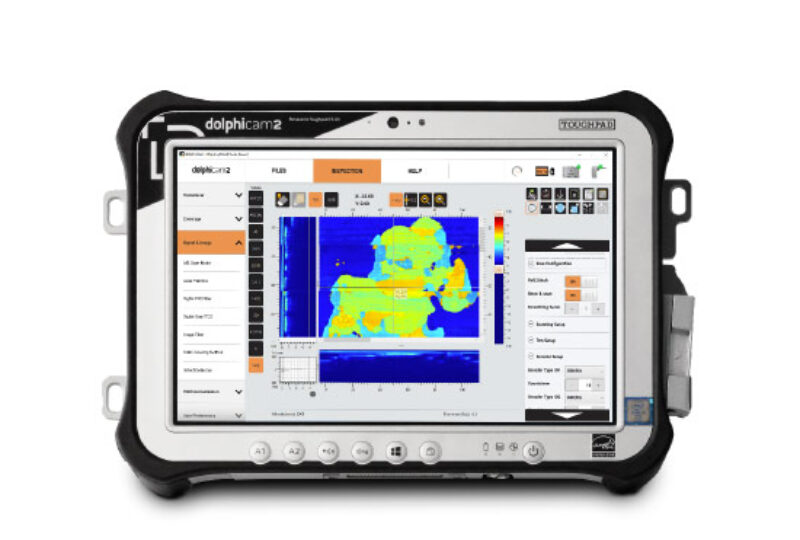

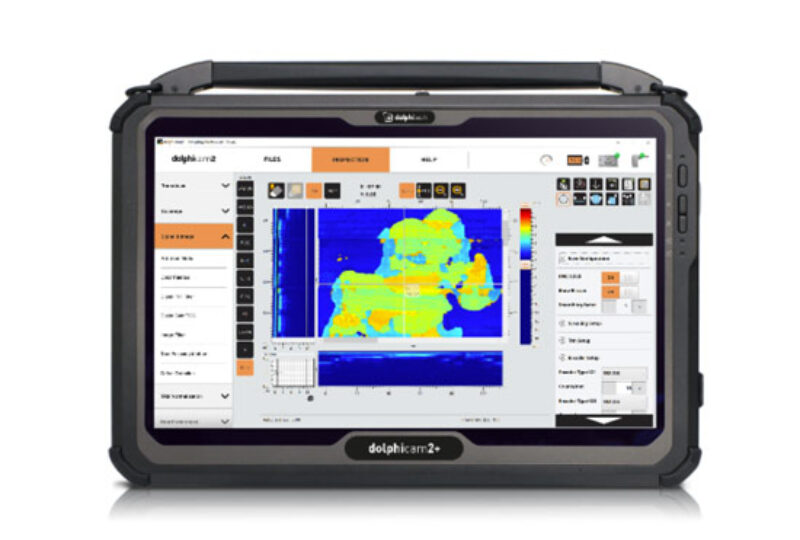

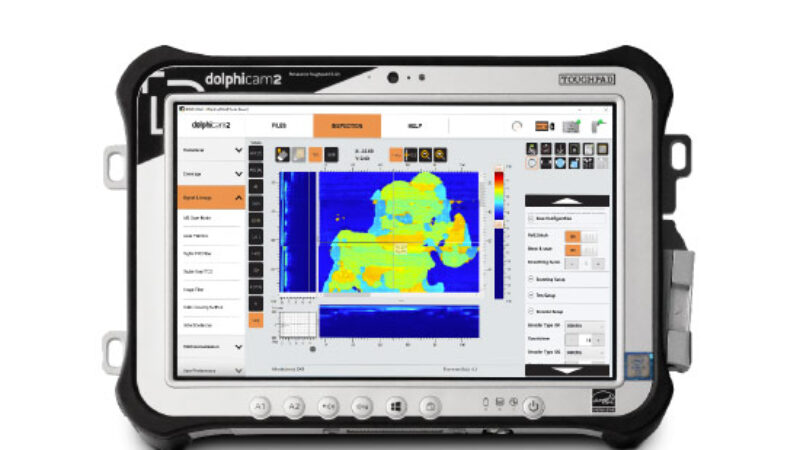

Our all-new MxTTU™ product combines advanced non-destructive testing technology with all the benefits of current TTU offerings. MxTTU™ is the only portable and practical device in the world that can offer the conclusiveness of live C-scans and simplified TTU evaluation. This means you can achieve the in-depth, high-quality diagnostics of traditional methods, in an easy-to-use, flexible handheld device.

There are several benefits of performing MxTTU™ versus standard Pulse-Echo (PE) systems, such as providing a larger inspection area enabling improved alignment for high precision tasks without sacrificing resolution or rate of evaluation. It also enables you to inspect materials that hinder sound propagation with high attenuation properties, such as multiple bond layers, honeycomb cores, or foam cores. Yet, one of the most valuable aspects of the dolphicam2 MxTTU™ system, is the unique design providing the ability to toggle between MxTTU™and Pulse-Echo mode without having to use another system or changing transducers making it quick and easy to use.

This latest version of our products, using our core Matrix transducer technology really changes the fidelity for how clients can use TTU systems, still only weighing 3kg and so portable, this is a go-anywhere system for manufacturers and for in-service inspection.

Eskil Skoglund – Chief Research Officer

This innovative new product from our team here at dolphitech was developed with the support of Spirit AeroSystems, who are one of the world’s largest manufacturers of aerostructures for commercial aeroplanes, defence platforms and contributed to the development of our MxTTU™.

It’s been great to support this innovation, for us, even if, for the sake of argument, a Matrix TTU scan could be done no faster than the current Phased Array PE system, the MxTTU evaluation will be completed far sooner and more confidently than for the PE data. This is where the Matrix TTU will really show its advantage. Conclusiveness thru Simplicity.

Mike Grosser – Technical Fellow, Spirit AeroSystems

We are recognised around the world for high-quality products and are dedicated to supporting our customers to ensure the reliability and integrity of their in-service assets and manufactured structures. So, whatever you need to inspect, from multiple-bond layers to honeycomb or foam cores, MxTTU™ makes non-destructive testing on complex structures and materials is far simpler – it’s the next-gen scanning solution you’ve been waiting for.