STUDY OVERVIEW

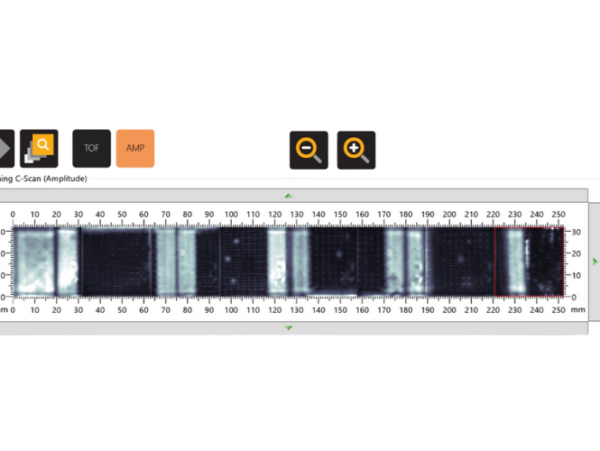

Stainless steels are used as a corrosion-resistant alternative to carbon steels across many industries, including power, construction and petrochemical. However, they may still be susceptible to corrosion in certain service environments, such as at high temperature or in the presence of chlorine. To evaluate the performance of the dolphicam2 for such inspections, we manufactured a stainless steel corrosion step block. At each step, the bottom surface of the block was machined to an undulating finish, with a range of additional holes also milled into it. This simulates the presence of general corrosion with additional localized pitting corrosion.

THE SOLUTION

A TRM-DA-10.00MHz was chosen for this inspection, since this high frequency enables superior image quality of the corrosion features. The short wavelength of the ultrasound at this frequency provides a high resolution to be achieved not just in C-scan images but also through the thickness of the part in the B-scan images. This makes the TRM-DA-10.00MHz perfect for inspections of thin metal components and structures, as well as for checking adhesive bond quality.

CHALLENGES

Stainless steels are typically more difficult to inspect than carbon steels for most NDT techniques. For ultrasonic testing, this is due to their larger grain sizes, which cause more attenuation of the ultrasound beams. In this study, the uneven back surface presented an additional challenge, in terms the ability to resolve the pitting corrosion features separately from the general simulated corrosion.

FINDINGS

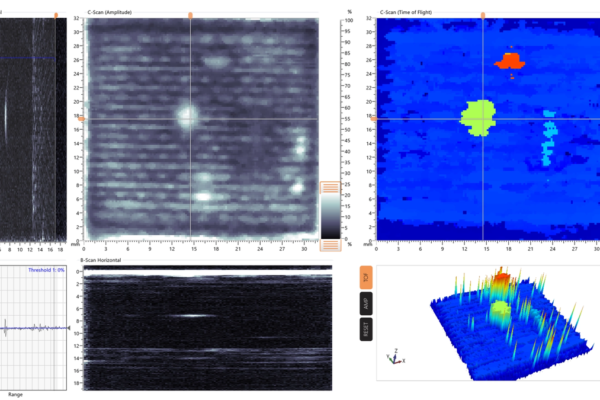

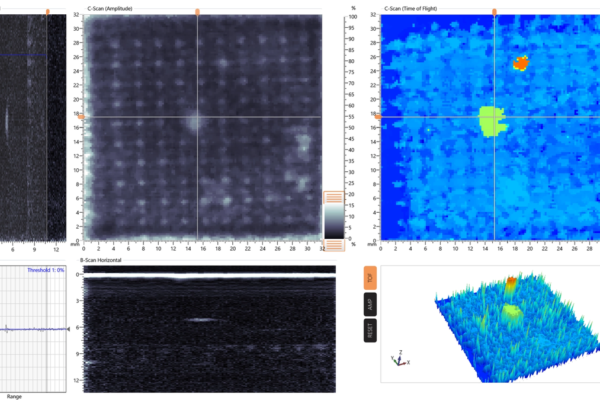

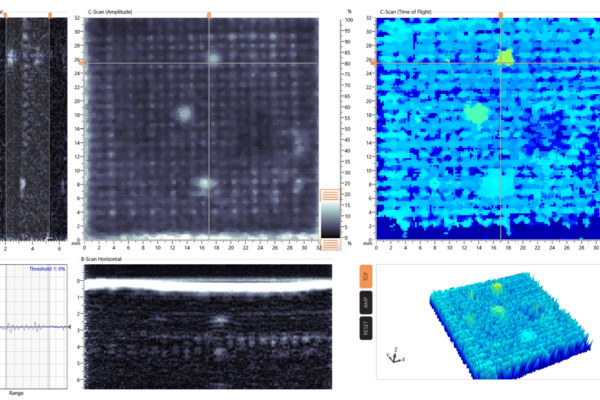

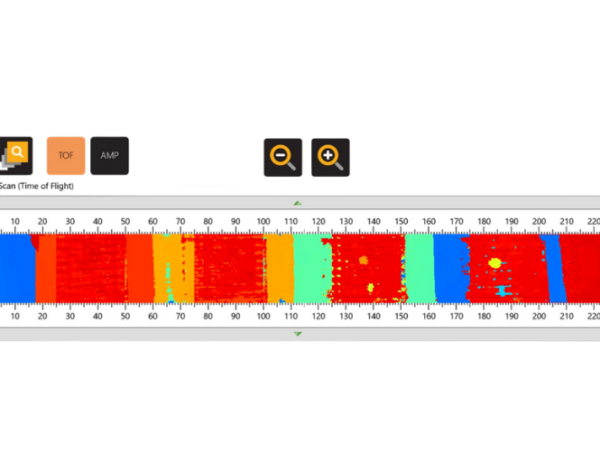

As shown in the images, the TRM-DA-10.00MHz was able to successfully resolve the pitting corrosion holes and differentiate them from the general inner surface corrosion. For this challenging inspection, the multiple views available prove invaluable for interpretation. At certain step block thicknesses, the pitting corrosion is more easily resolved in the amplitude C-scan (grayscale), whereas at others it is more apparent in the Time-of-Flight C-scan (color). Having both available live, while also showing the two B-scans and 3D view, provides users with the maximum amount of information to help characterization.

CONCLUSION

The dolphicam2 with the TRM-DA-10.00MHz proved well-suited to this challenging inspection of pitting corrosion in stainless steel. Through combining our powerful core TRM technology with an intuitive set of live image displays, complex inspections become easy to interpret.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.