OUR TECHNOLOGY AND PRODUCTS MEET THE STRICTEST

INDUSTRY STANDARDS

Safety is the single most critical aspect of aerospace whether that be aeroplanes, helicopters or drones. Non destructive testing (NDT) is used throughout a product’s lifecycle from the qualification of new materials and the designing of new aircrafts to in-service inspections of aircraft structures and engines. Within aerospace, NDT plays a vital role in the design, manufacture and maintenance processes. The dolphicam2 uses NDT technology to examine.

AIRCRAFT MAINTENANCE AND INSPECTION

Dolphicam2 is certified by two of the world’s leading aircraft manufacturers – Boeing has authorised specific NDT procedures for their 787 aeroplanes, and Airbus has accepted the dolphicam2 for all composite inspections on its assets.

Dolphitech leads the market in NDT of composite materials. Our flagship product, the dolphicam2 is a hand-held, easy to use, ultrasonic scanning tool that produces real-time, analysis-ready imagery of composite, metal and multi-materials with the most accurate and highest visual quality.

INNOVATIVE NDT TO ENSURE THE INTEGRITY OF YOUR ASSETS

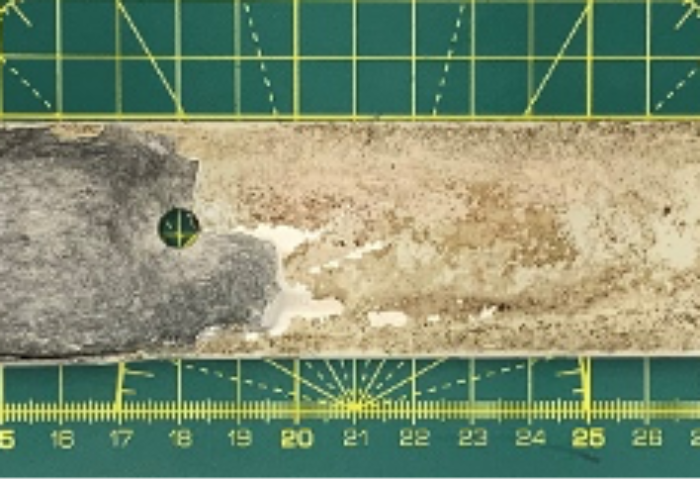

Inspections include multiple scenarios such as impact damage, mapping corrosion and metal fatigue in the fuselage, inspecting wings or blades for fatigue damage, disbonds and cracks detection.

CASE STUDIES

Learn how dolphitech has revolutionised the world of inspections for our customers

UNRIVALED FLEXIBILITY FOR AIRCRAFT AND HELICOPTER MAINTENANCE

Our all-new MxTTU™ product combines advanced non-destructive testing technology with all the benefits of current TTU offerings. MxTTU™ is the only portable and practical device in the world that can offer the conclusiveness of live C-scans and simplified TTU evaluation. This means you can achieve the in-depth, high-quality diagnostics of traditional methods, in an easy-to-use, flexible handheld device.

COMPREHENSIVE TRAINING AND SUPPORT

The Dolphicam2 platform requires minimum training to operate. We offer training and support so you can inspect and gather high accuracy and visualised data wherever and wherever it is required. The platform will be ready to use in 60 seconds, increasing efficiency and saving you valuable time between site visits. No more downtime while calibrating your hardware either.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.