STUDY OVERVIEW

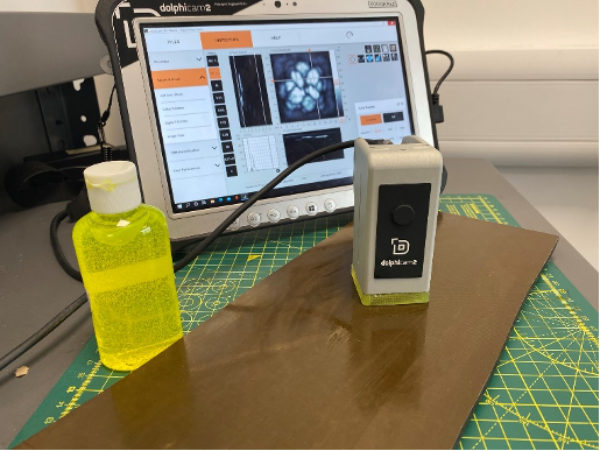

We performed a non-destructive test (NDT) trial on several samples of Carbon Fibre Reinforced Plastics on aircrafts, using the easily deployable dolphcam2 Ultrasonic platform.

Aircrafts can be subject to impact damage when parked on the Tarmac between flights. With several heavy equipment moving around it, such as Catering Trucks, Loaders and Jetways. When an impact happens, it is imperative that the area is inspected quickly and thoroughly.

The client was keen on observing the dolphicam2 results, and to compare the results and performance of the kit to legacy methods. the usual method of inspection calls for timely Guided A scan inspection. These inspections are time consuming and require a well trained technician to interpret the A scan readouts.

THE SOLUTION

The benefit of the dolphicam2 is it’s highly adaptable and has a wide range of scenarios, applications and materials that it can be utilised for which makes it suitable for almost any industry.

Different transducers can be utilised depending on material type, area and thickness of material being tested. This ensures that the most effective results are always achieved.

The dolphicam2 solution is also extremely portable and easy to use, which cuts down the time taken to physically inspect. The platform will be ready to use in as little as 60 seconds, making it the fastest in the industry.

During this specific project, a transducer 5.0 MHZ with an 8mm delay line, provided suitable penetration power for the CFRP material, as well as outstanding resolution for identifying the damaged area and depth affected, in a fraction of the time needed for the guided A scan procedure.

CHALLENGES

Our customer was keen to understand the effectiveness of our dolphicam2, in order to assess impact damage to the aircraft over legacy inspection procedures; as well as the need for extensive training of technicians located in many bases throughout their network.

FINDINGS

Boeing 787 Fuselage Skin Impact Damage

A sample was made available for inspection, with induced impact damage. The image (below) is of the sample a 5mm thick Skin sample from a B787 aircraft.

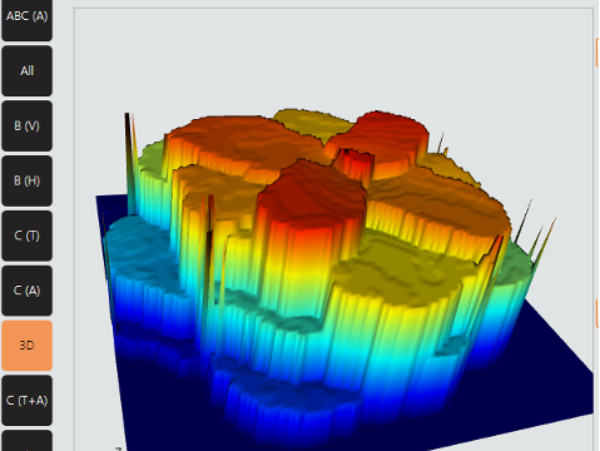

DOLPHICAM2 RESULTS

The comparison between our technology and traditional inspection is demonstrated through the results we were able to achieve for our customer:

– The dolphicam2 was able to fully penetrate the material, identifying layers of material and impacted areas.

– Our equipment was able to review and test the sample very quickly and with minimal set-up time for the equipment.

– Impact damage on CFRP Aircraft skins and similar surfaces cause little or no change to the outer skin; sometimes this is called Barely Visible Impact Damage (BVID) and are hard to detect and evaluate. However the dolphicam2 made it easy to screen for these traditionally hard to find indications in a time critical and highly regulated operation, where the decision has a huge safety and financial impact.

CONCLUSION

We clearly demonstrated that the dolphicam2 provided quantitative data for damaged areas of the sample, allowing engineers to assess whether to ground the aircraft or release it for flight operations. Aircraft inspections have been carried out on the tarmac on other occasions with success, due to portability and ease of use. Thanks to our non-destructive evaluation, data was quickly uploaded and shared with experts both at the client’s main maintenance facilities, in addition to the aircraft manufacturer’s engineers for post processing and deeper analysis.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.