STUDY OVERVIEW

EXECUTIVE SUMMARY

A simple case study was performed on a 170mm (about 6.69 in) carbon steel pipe to measure the remaining thickness from artificial corrosion. The pipe was ground with an angle grinder from the inside to simulate corrosion or wall thickness loss. dolphicam2 and a 5MHz no-delay-line TRM were used with an irrigated pipe shoe and water supply system to demonstrate effective and accurate measurement of remaining wall thickness.

INTRODUCTION

Due to its cost-effectiveness in manufacturing and welding, carbon steel is still the most widely utilized piping material in the O&G industry compared to its stainless steel, alloys, and non-metallic alternatives. The main downside of carbon steel is its lower corrosion resistance compared to those alternatives. If corrosion goes beyond the critical threshold, it will lead to pipe fracture, resulting in financial loss and even worse, loss of lives. It is important to regularly inspect the pipe wall thickness and closely monitor regions where corrosion has started. It allows for the proper scheduling of maintenance work or replacement of damaged sections with minimum impact on the operation.

The most common corrosion mechanism for carbon steel pipes is general corrosion on the internal surface where the wall thickness gradually reduces from the impact of its liquid content. One major challenge in corrosion monitoring is producing fast and accurate readings with a digital record. dolphicam2’s unique probe design allows for coverage of a much larger area in one pass while maintaining measurement accuracy.

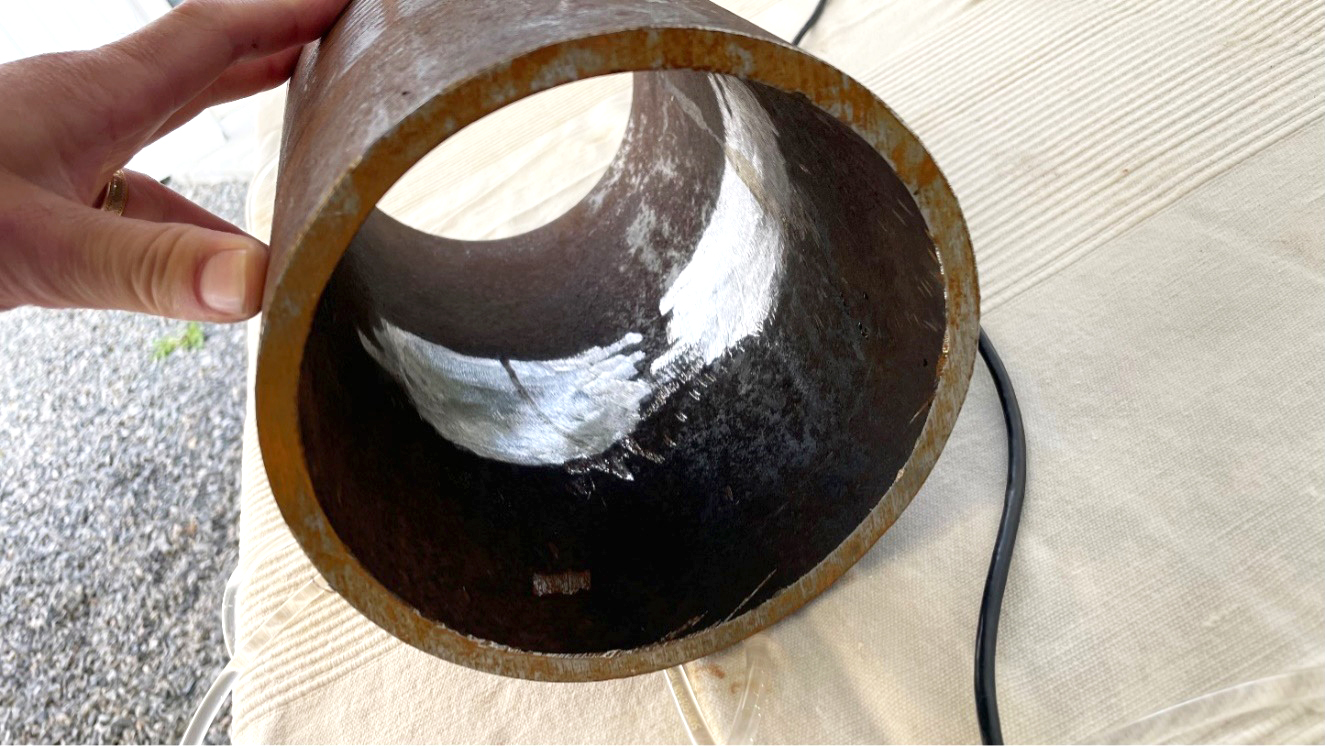

This case study demonstrates dolphicam2’s ability to inspect general corrosion and remaining wall thickness. The test target is a section of carbon steel pipe with circa 170mm (6.7 in) diameter and 8mm (about 0.3 in) original wall thickness. Part of the inner wall was ground with an angle grinder to simulate corrosion, as shown in the figure below.

SOLUTION

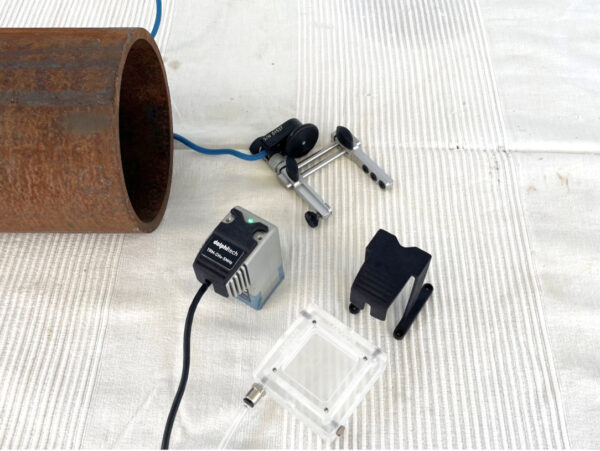

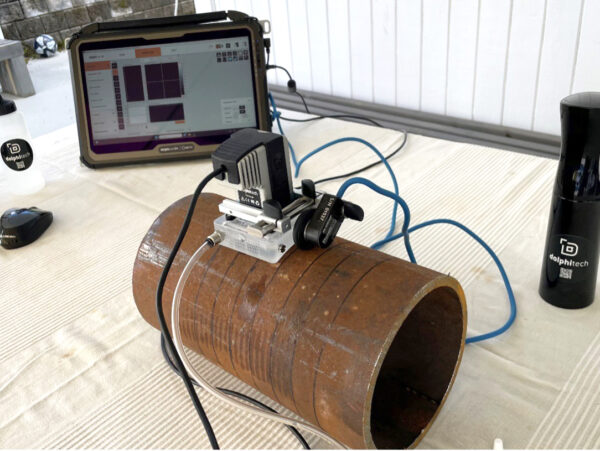

The dolphicam2+ was used with a water-irrigated pipe-shoe and a 5MHz, no-delay-line transducer module, TRM-CHx-5.0MHz. A wheel encoder was used to scan an area of the pipe. It is important to note that a chain scanner or a magnetic scanner/crawler can be used for semi-automated and automated inspection. The positioning accuracy will be improved using a chain or magnetic scanner/crawler. For general corrosion and remaining thickness inspection on carbon steel, the 5MHz TRM gives the best combination of ultrasound penetration and depth resolution in the ultrasound data. A manual water pump was used to provide water pressure to the irrigated pipe-shoe.

CHALLENGES

The main challenge in this application was coupling to the rough surface.

In this case, continuous water flow through the water-irrigated pipe-shoe was chosen to provide the best consistency.

FINDINGS

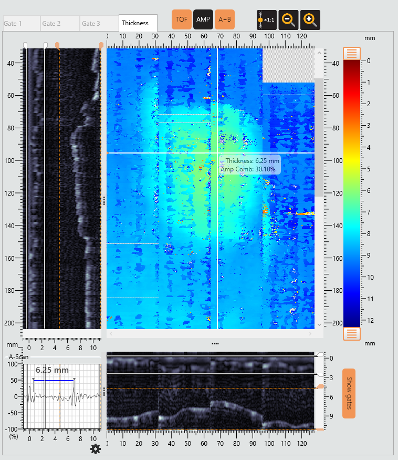

The ultrasound results show a gradual reduction in wall thickness in the “corroded” area. The C-scan Time-Of-Flight image is easy to interpret where areas that are blue do not have corrosion. Wall thickness down to 6.25mm was found in the scanned area of the pipe (the original wall thickness was 8mm).

ToF C-scan clearly highlighted regions where a reduction in thickness has occurred. The colour-coded C-scan provides the first impression of the severity of the thickness loss, and additional measurement tools provide the exact reading of the remaining wall thickness.

B-scans outlined the profile of the thickness reduction, further highlighting the corrosion pattern including the thinnest part and the angle of the corrosion.

CONCLUSION

The dolphicam2, together with the 5MHz TRM, can be used to successfully inspect and evaluate corrosion or the remaining thickness of a carbon steel pipe. Detailed measurements can be obtained for every 0.25mm (about 0.01 in) in the scanned area and with a very high thickness resolution. The water-irrigated pipe shoe works great together with a no-delay-line TRM and is easy to set up with a manual pump.

Effective and accurate corrosion scanning can also be done with a pipe chain scanner and magnetic pipe scanners.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.