STUDY OVERVIEW

Adhesive bonding is an attractive joining option for numerous applications, as it can be readily implemented in an industrial manufacturing process, it eliminates the thermal distortion associated with welding, and the deformations and stress risers associated with mechanical fastening. It is particularly well-suited to thin sheet applications and for joining of dissimilar materials, where it is used across many markets, including automotive and aerospace. To assess the capabilities of the dolphicam2 for inspecting such adhesive bonding, the Research Institutes of Sweden (Ri.Se) kindly provided us with a strap lap joint. The two side pieces were 2mm thick steel, while the central bridge was 1mm thick aluminum. Within the two adhesive bonded regions, PTFE reflectors of various sizes had been inserted.

CHALLENGES

The TRM-DB-8MHz (8 mm Rexolite) was used to inspect the lap joint from the aluminium surface. This higher frequency transducer is capable of the near-surface resolution required for thin-wall applications. A manual stitching technique was used to cover the lap joint area of 136x56mm.

FINDINGS

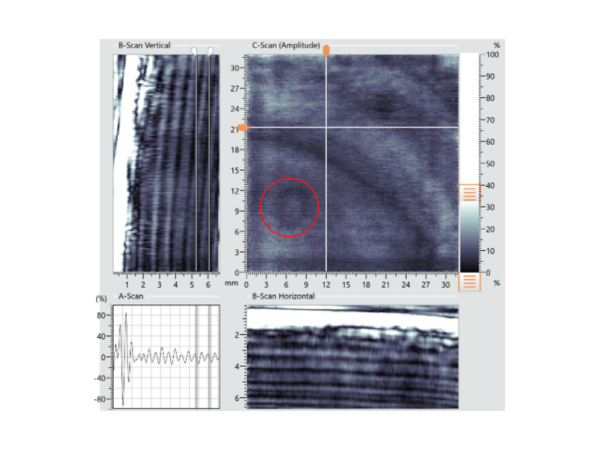

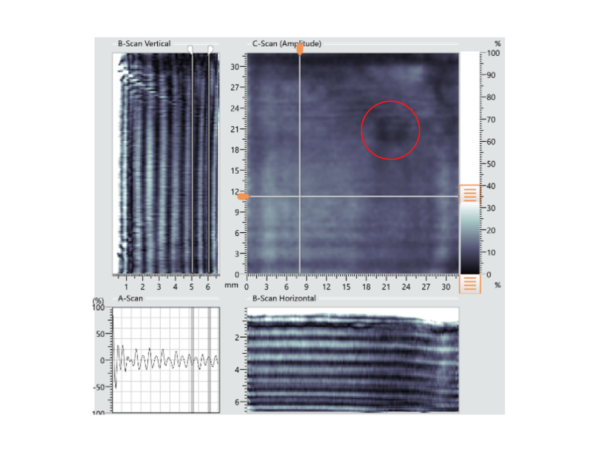

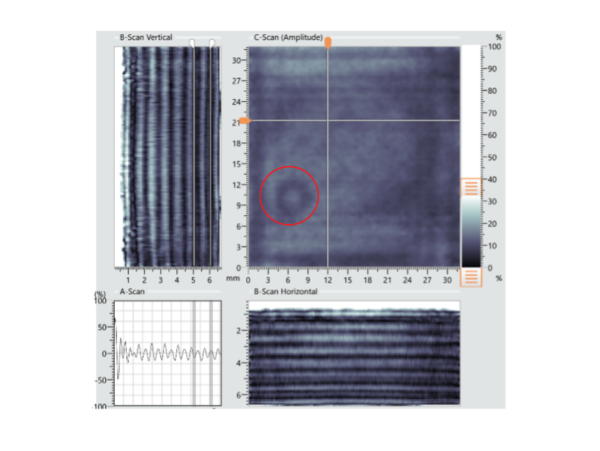

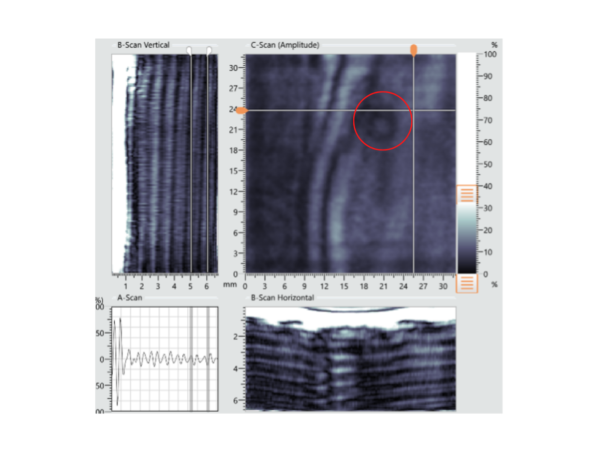

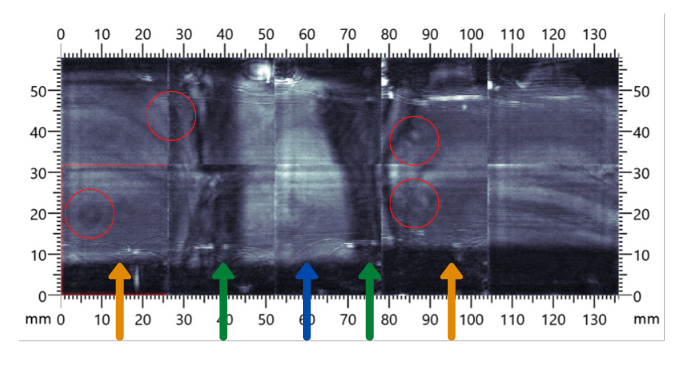

Despite these challenges, the TRM-DB-8MHz was able to successfully inspect the adhesively bonded joint and resolve the PTFE inserts (red circles). This was achieved through careful gating of the back wall signal amplitude, which enabled maximum sensitivity of the interfacial signal response to be achieved.

The stitched C-scan was also able to highlight the different backing materials present via the back wall signal amplitude. At the adhesively bonded regions, a medium amplitude back wall response was observed (medium gray color, denoted by orange arrows). At regions with excessive adhesive spill-over, more sound was transmitted into this adhesive and damped by this material, reducing the back wall amplitude (dark gray color, green arrows). In the central portion of the lap joint where no backing material was present, the back wall of the aluminium, the highest amplitude was observed (light gray, blue arrow).

CONCLUSION

The dolphicam2 was able to successfully resolve small reflectors within an adhesive bonding layer between two metal sheets. In addition, the ability of the dolphicam2 to resolve different general back surface contact conditions was also highlighted. This result demonstrates the versatility of the dolphicam2 with the 8MHz TRM, which is also well-suited to inspection of thin composites.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.