INSPECTION OF METALS

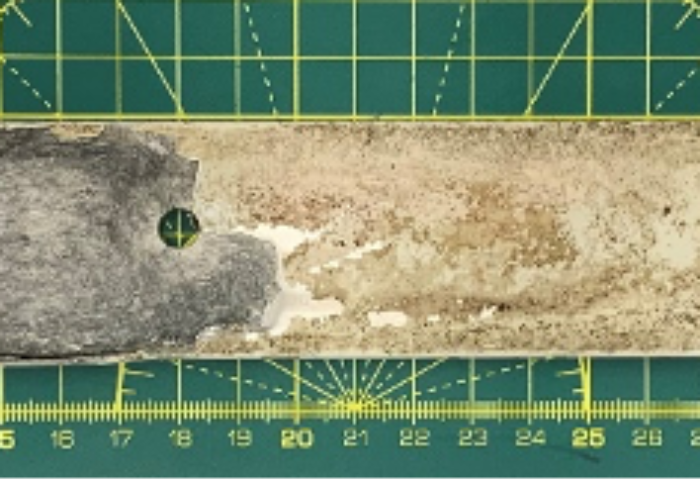

For metallic inspection, where zero degree (compressional) applications like thickness measurement and mapping, corrosion inspection, cracking and laminar flaw detection are needed. dolphicam2 and Matrix Array (MAUT) is the perfect choice.

dolphicam2 offers the highest number of data points (16,384 A-Scans across a 32x32mm area) than any other system on the market. Live C-Scan technology give the user instant and clear information about the condition of the material under inspection. dolphicam2 is easy to use and data easily interpreted, view and sentence live or save data rich FMC (Full Matrix Capture) files for analysis on or off the instrument.

Find the materials that are relevant to you in the handy matrix below and see what the dolphicam2 can do for your inspection.

EXPERIENCE THE DOLPHITECH DIFFERENCE

See more with our innovative NDT technology

Send in a sample to see how dolphitech can reduce inspection lead times and enhance insights

Contact usREQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.