INSPECTION OF BONDED STRUCTURES

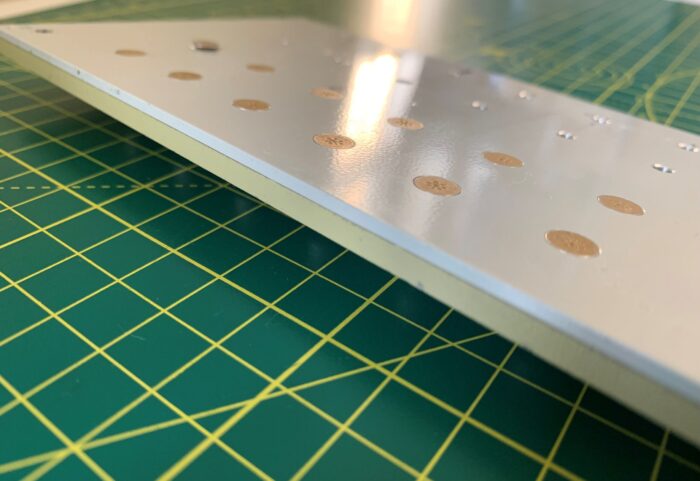

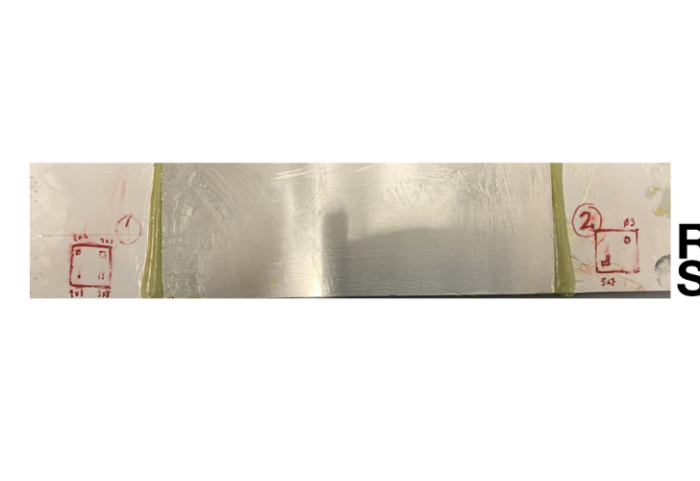

Matrix Array Ultrasonic Testing (MAUT) technology is particularly effective for inspecting bonded materials. dolphicam2 provides real-time C-Scan data, offering users a detailed and immediate view of the material’s condition. Whether you’re checking for defects during manufacturing or assessing in-service materials, the dolphicam2 stands out as the preferred choice for quick and reliable inspections.

One of the key advantages of the dolphicam2 is its ability to capture an exceptionally high number of data points—16,384 A-Scans within a 32x32mm area. This density of data points surpasses any other system available, ensuring a comprehensive analysis of the inspected material. The live C-Scan technology delivers instant, clear information, allowing users to make informed decisions on the spot.

The dolphicam2 is designed for ease of use, with intuitive data interpretation. Users can view the results live or save the data-rich Full Matrix Capture (FMC) files for further analysis, either on the device or externally. This flexibility makes it a versatile tool for various inspection needs.

To help you find the most relevant materials for your specific requirements, we provide a convenient table below. This table highlights the capabilities of the dolphicam2, demonstrating its effectiveness in different inspection scenarios. Whether you’re dealing with composite materials, metals, or other bonded materials, the dolphicam2 can enhance your inspection process with its advanced features and user-friendly interface.

EXPERIENCE THE DOLPHITECH DIFFERENCE

See more with our innovative NDT technology

Send in a sample to see how dolphitech can reduce inspection lead times and enhance insights

Contact usREQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.