HELPING SAFEGUARD AGAINST MANUFACTURING DEFECTS

Safety and reliability are key factors for a consumer when considering the purchase of a new vehicle. With the global automotive industry ever-changing, manufacturers must ensure that each chassis or component built and every vehicle assembled, is consistently compliant with stringent international industry safety and regulatory standards. With increasing reliance on modern, lightweight composites and multi-materials that interface with high-performance metals, the industry relies on non-intrusive inspection techniques such as ultrasonics to detect flaws in safety-critical components.

SPEED, ACCURACY, AND RELIABILITY

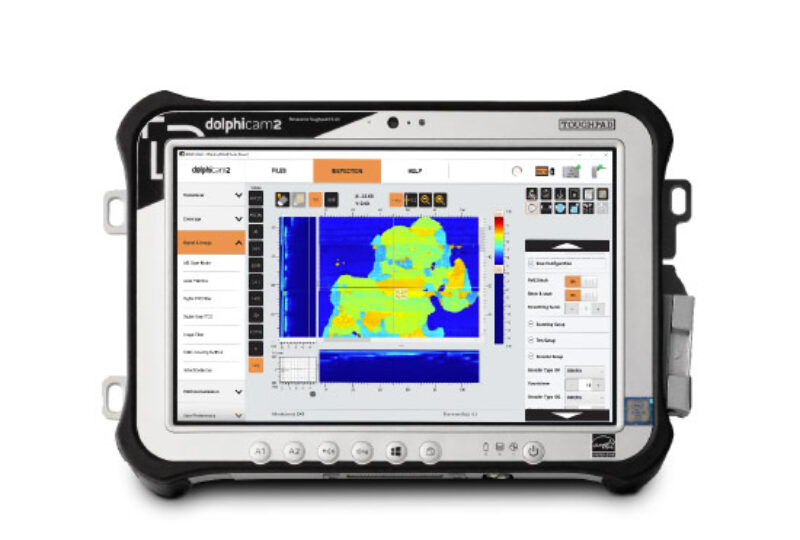

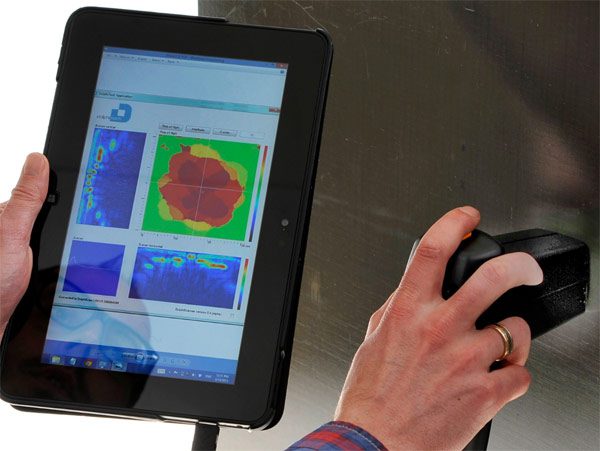

The most effective way to perform manufacturing inspections is with dolphicam2. The dolphicam2 can visualize, characterize and measure even the smallest of defects. Our experienced dolphitech team are solvers by nature and are dedicated to supporting customers to achieve the highest standards of component safety.

Our original technology was adapted to read barcodes printed on the bare metal of the chassis through multiple layers of coatings and paint, negating the need to scrape back the paint to find serial numbers. The dolphicam2 allows our customers to make accurate, consistent, detailed NDT a straightforward and cost-effective task.

INNOVATIVE NDT TO ENSURE THE INTEGRITY OF YOUR ASSETS

Dolphitech’s flagship Ultrasonic Technology (UT), dolphicam2 is an ideal platform to detect and inspect damages, defects and degradations. The dolphicam2 is flexible, easy to deploy and handheld, making it the ultimate tool for fast inspections.

CASE STUDIES

Learn how dolphitech has revolutionised the world of inspections for our customers

FULL TRAINING AND SUPPORT PROVIDED

The dolphicam2 platform requires minimum training to operate. We offer training and support so you can inspect and gather high accuracy and visualised data wherever and wherever it is required. The platform will be ready to use in 60 seconds, increasing efficiency and saving you valuable time between site visits. No more downtime while calibrating your hardware either.

REQUEST A QUOTE OR SUBMIT AN ENQUIRY

Need help with product information?

Get in touch with our experts for information or a quotation.